|

|

|

|

|

You are not logged in. Would you like to login?

![]() Offline

Offline

on May 3, 2010, 10:27 am Joe wrote:

The cover was powdercoated and then filed off the powdercoat on the fins and polished the aluminum. The drain plug was purchased from McMaster-Carr P/N 4464K254 for $3 so I went ahead and polished it also

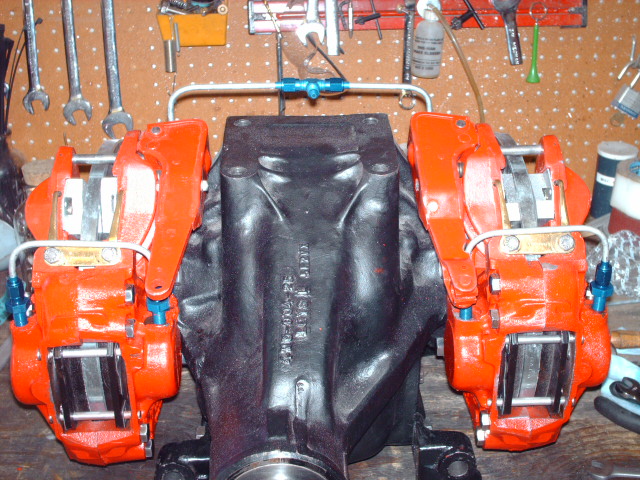

Everything that I have read about the Jag brake lines/flares was that the Girling flare was not very good. The flare actually molds to the bottom of the hole in the caliper so the first time you tighten it down it works great. After that however there are no guarentees. I found an article by a guy that builds race cars in Britain somewhere. He stated that he uses -3an bulkhead fittings so I gave it a try and they work really well. I just wish they were a little shorter. I could only find one length. Summit AER-FBM2769 $3.75 ea A little pricy but not too bad.

I dissassembled the parking brake mechanism and removed all of the self adjusting hardware. It was clear from the condition of old pads that came with the IRS that the self adjusters were just something else to go wrong. You can't see it in this photo but the rod that runs through the backside is actually threaded so I can adjust the parking brake manually and then run a cotter pin through the hole where they used lock wire.

![]() Offline

Offline

on May 3, 2010, 12:09 pm cecil671 wrote:

Joe,that looks fantastic.

Thanks for the brake info too.

Where did you get the rebuild kits for your calipers?

Last edited by Daze (10/07/2011 1:52 pm)

![]() Offline

Offline

on May 3, 2010, 1:36 pm Joe wrote:

Funny story ... I needed all four pistons and the rebuild kit. After lots of searching, I found a place "across the pond" that had the pistons for a reasonble price and the rebuild kits. The pistons were perfect but the rebuild kit was wrong so I ended up buying from rockauto.com.

![]() Offline

Offline

on May 3, 2010, 5:30 pm Daze wrote:

Thats a great tip on the break lines, I will be printing this post out and...

putting it in my IRS archive. Where did you get the cover?? all the ones I have seen are either really expensive or do not have a spot for the vent. Can you give us more details on the self adjustment mechanism, or at least the elimination of that part?? I am really glad you joined the forum Joe!!!

![]() Offline

Offline

on May 3, 2010, 6:19 pm, Joe wrote:

The cover was from Speedway motors P/N 92547009 $90 for the unpolished aluminum one. The only problem I had was I needed to shave off one side of the washer on 2 or 3 pieces. The original steel unit obviously didn't need washers.

I need to get you a picture but the short version is I welded a nut to a flat piece of metal. The metal keeps the nut from turning inside the housing. The threaded rod is the stock Jag piece.

![]() Offline

Offline

on May 5, 2010, 3:38 pm farna wrote:

I haven't had a leaking problem with the lines on mine, and they are original. I just used a standard flare junction block to tie into the original US type rear brakes line -- haven't noticed any leaks there either. I just got it off the rack to fix the radius rods.

I used standard 24" four link rods with screw-in urethane bushed rods ends on one end (end at axle). I noticed that the ends screwed in and out just a little as the axles move, but never took them off and greased the threads. Should have! After six years and about 30K miles one end pulled out! The threads were worn down. Nothing disastrous happened, the car just started pulling to one side a bit (the threads were coming out about 1/2" -- threaded in the rod over an inch) and I thought it was a brake sticking. Wasn't in a big hurry to look at it, wasn't very bad. Then it pulled a LOT one day and every time I gave it some gas OR put on brakes I could tell the car wanted to "crab" a little. Drove it a bit gingerly home and put it on the rack. Guess I hit a pot hole or something and pulled the rod end completely out. This was on the power side (right side -- standard diff) -- the other side was fine.

I welded the lock nut (which I kept loose) on the end of the rod, slathered anti-seize on the threads, and put it back together. Did the same to the other side, which showed some wear, but not near enough to be in danger of coming out. I'm going to order a new set of rods and ends though, the welded nut is just to last a few weeks or months until I get the new ones in. Not bad -- 30K+ miles and six years to wear the threads out of a totally dry rod! I'll use anti-seize on the new ones then pull and re-coat every 2-3 years (I don't put as many miles on it as I used to, so every 10-15K miles). Not thick enough for a grease zerk. That should be fine, considering the 30K+ before it wore out with NO lube at all.