|

|

|

|

|

You are not logged in. Would you like to login?

1 of 1

1 of 1

![]() Offline

Offline

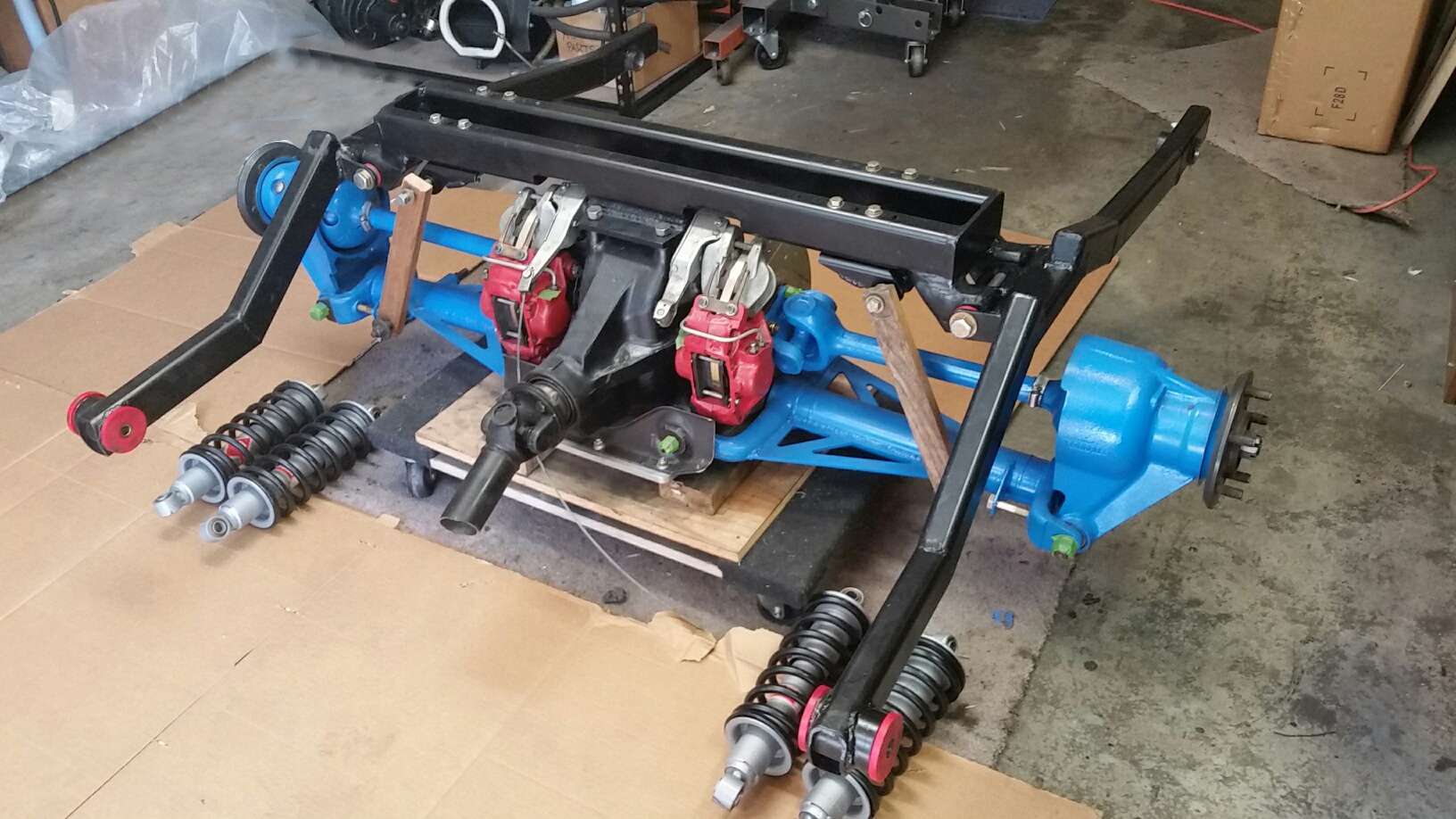

I'm going to post some pics (if I can figure out how), and show you how Dave's design was built up and installed - bolt in - to my '68 Mustang Coupe

Last edited by Chuwers (2/03/2017 3:52 pm)

![]() Offline

Offline

![]() Offline

Offline

I mocked it up in wood first, then welded up the three main pieces; side rails and cross-member.

![]() Offline

Offline

Here's where the cross member attaches to the side rails. Two sets of poly bushings and flanges, with a 5/8" Grade 8 bolt through 'em. The frame tubing is 1 1/2" x 2 1/2" by 0.188" wall.

is 1 1/2" x 2 1/2" by 0.188" wall.

![]() Offline

Offline

Then, I bolt the front of the side rails through the forward leaf spring hard points, and swing up the rear

![]() Offline

Offline

This (not very clear) shows the rear end swinging up into place, pivoting on the forward rail bushings.

![]() Offline

Offline

Once in place, I use the original shackle links to pin the rear in place.

![]() Offline

Offline

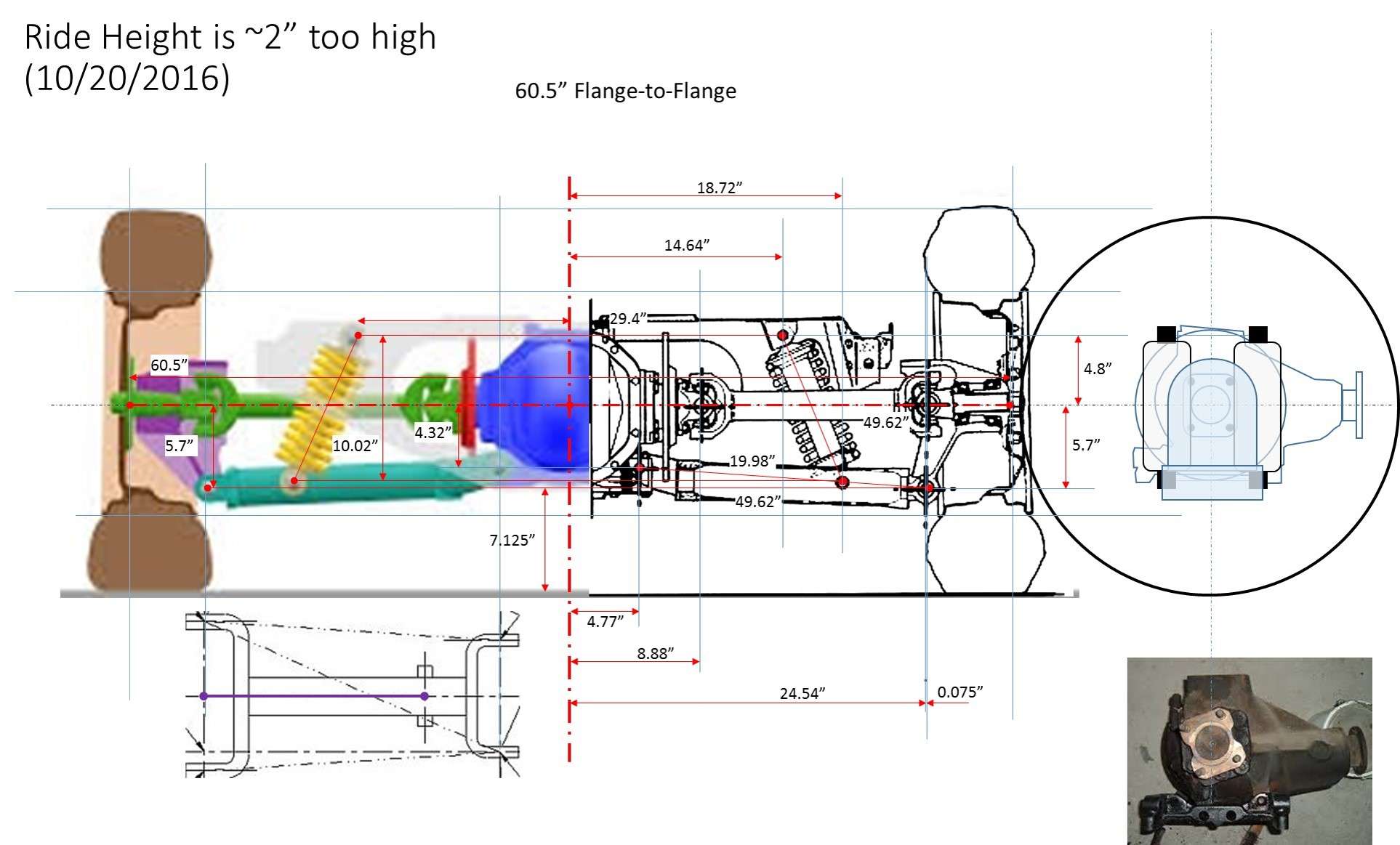

The spring adjustment details are shown here. At first run, I was about 2" too high, so I got shorter, stiffer springs, and now they're perfect. (IMPORTANT NOTE:, the '67 & '68 Mustang have 2" wider flange-to-flange distance on the original car, so shortening the LCA and half shafts is not necessary.)

![]() Offline

Offline

![]() Offline

Offline

Since I have welded in TCP Frame Connectors and stiffener, I have a convenient place to bolt in a pair of torque arms.

![]() Offline

Offline

Then, added the anti-sway bar. If you notice, there's still about an inch left on the bolt where the original Jag radius arms attached. My future plan is to build Watts linkage style radius arms (going straight forward and aft to the chassis, with a pivot at that bolt) to react the loads at the LCA.

![]() Offline

Offline

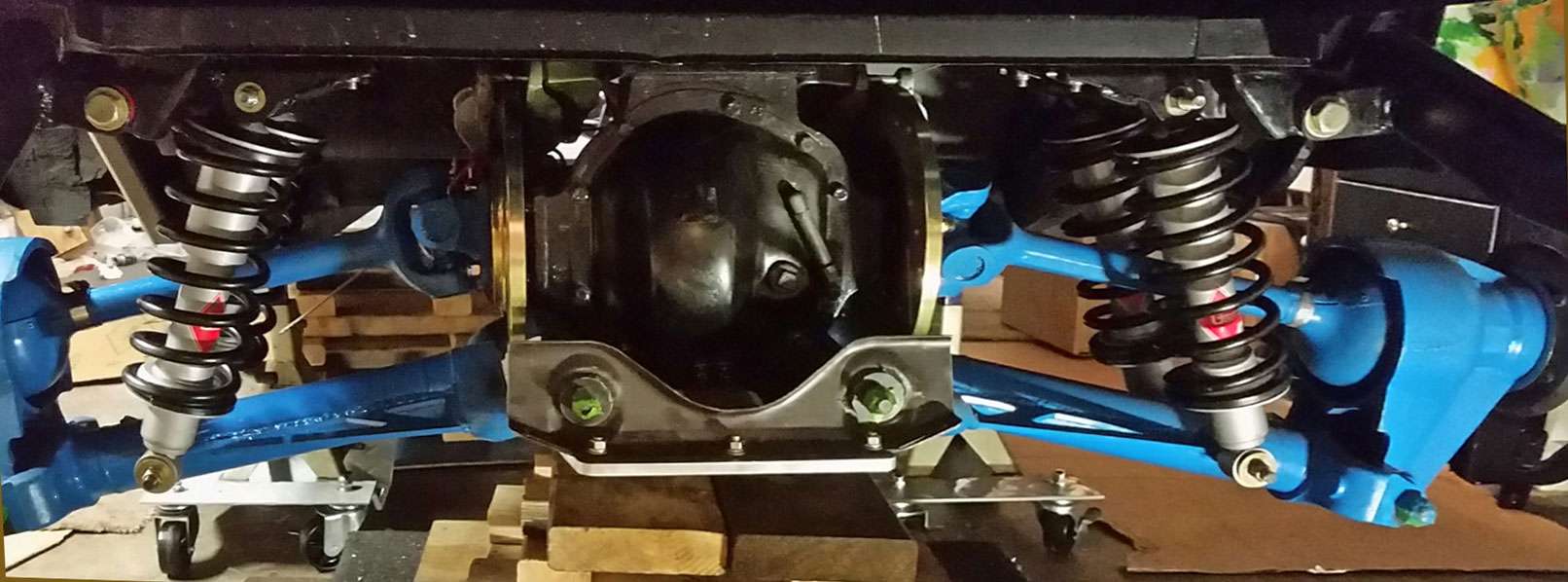

Here's a view from the rear, up into the left side of the IRS.

![]() Offline

Offline

By the wat, just for kicks, I had one of the local high school geniuses do this whole thing in CAD (Inventor), and made a few adaptations on the as-built. Here are my starting dimensions (elevation view).

![]() Offline

Offline

Stepping back a bit, here's the wood mock up, and the subframe prep.

![]() Offline

Offline

Here she is today.

![]() Offline

Offline

Also a little peak under the hood (I hope you don't mind). 351W stroked to a 408.

![]() Offline

Offline

And a Mustang II front clip.

![]() Offline

Offline

I have more pics, drawings, and can offer some tips from my experience. ONCE AGAIN .... ALL CREDIT TO DAZE!!!! YOU WILL RECOGNIZE HIS INSPIRATION FROM THE PICS HE POSTED LONG AGO! HE LED THE WAY, I FOLLOWED.

![]() Offline

Offline

I do not see any signs of narrowing on your IRS. Did you leave it at the XJ6/12 width?

![]() Offline

Offline

How does it handle?? That looks like a fantastic install, in fact I am extremely impressed, especially with the upper shock mount, what a brilliant way to make them adjustable. Thats a lot cleaner than the way I did it.

Chuwers wrote:

I have more pics, drawings, and can offer some tips from my experience. ONCE AGAIN .... ALL CREDIT TO DAZE!!!! YOU WILL RECOGNIZE HIS INSPIRATION FROM THE PICS HE POSTED LONG AGO! HE LED THE WAY, I FOLLOWED.

I will take everything you have in the way of pix and drawings and add them to the database I use to help others can you email it to me? day at dazecars dot com

![]() Offline

Offline

For Tyrell Racing. Correct. The '67/'68 is two inches wider flange-to-flange than the '65/'66. I didn't shorten the LCA or half shafts. What I did need tho', was wheels as follows: 16"x8"x5.25" BS Torq Thrust.

Note the large backspacing. That pulled my rear wheels back in. Since the Jag IRS is a Chevy bolt pattern, and I wanted same wheels all around, I needed wheel adapters in the front, to go from Ford to Chevy. So, I got the 1" thk wheel adapters in front, and the high backspace wheels with Chevy bolt pattern all around. Long winded answer, but I hope you get it.

![]() Offline

Offline

For Daze. It handles really well, altho' so far haven't really stressed it. I'm still working the "shake down cruise", or might I say "flight testing". It is totally stable, straight line under acceleration or braking. Feels tight and confident. Once I get 500 miles on her, I'll take her down to the skid pad, and maybe run an autocross or two, then report back.

Thanks again, Day !!!! Nice work!!

![]() Offline

Offline

So will you email me every thing you have?

![]() Offline

Offline

I sent three bundles to you. The "whole enchilada" is 172 MB consisting of 322 files. That'll choke my outbox. A lot of it is public info - website data and junk like that. I sent you most the original work. Cheers!

![]() Offline

Offline

got it, Thanks!!!

![]() Offline

Offline

Unless you have any objections I am going to take the info from this post and put in on a new DazeCars "Mustang IRS success stories" web page. I get a lot of emails of people asking if I ever finished the project and I think what you have done will be a lot of help to them.

![]() Offline

Offline

Follow-up: The '68 Mustang, "1FSTPNY", has been "out-and-about" for 6 months now. After a few hundred miles of "test flights" and some slight suspension tuning I went up to an autocross being held at Shelton (WA) airport. I decided, "If I'm gonna break 'er, I'm gonna do it today". And proceeded to mash the course. Man, the results give me a rush of pride, and same should go for you! Absolutely exceeded my expectations. With the locker rear end, she grabbed the course and just tore it up. Flat, solid and steady even around the tightest turns at each end. Just a little over-steer, perfect for feeling a nice, smooth, controlled transition as traction slips. No jump, shudder or hopping, at all. I can get the rear to come around nicely and set up for the straights. The slaloms were tight, with almost zero body roll. The TCP frame connectors locked the chassis; front to rear, and the Mustang II coils overs with rack & pinion in front .... altogether a fine driving experience!

NOTE - The aluminum torque arms began getting loose in the threads, so I went with steel. Also added side plates over, and just outside, the wheel arch (belt and suspenders) just to add some stiffness in that high stress area of the side rails. Final weight distribution, with full tank of gas and driver, is 51% Front, 49% rear.

![]() Offline

Offline

Question? What gear ratio are you running?

1 of 1

1 of 1