|

|

|

|

|

You are not logged in. Would you like to login?

![]() Offline

Offline

It's interesting almost every person responded with the same answer on Heim ends. However every application has it's own set of criteria. Needing to define your applications scope. This is why a person doing their own IRS build need not go blindly into modifications. Some instances however, a Heim meets the builders criteria very well. A low weight or race application are two of these areas. This also shows the importance of having a board such as this to help guide a novice in a more intelligent path. Why are people using Heim's? You can't build a suspension any lighter with less drag in any other way. These are needs for a racers application.

I have a possible alternative that is still fairly light and performs with little (friction) load. Once I thought of a solution, I found others who did something of the same.

Last edited by Ralphy (3/05/2012 9:13 am)

![]() Offline

Offline

I have seen those rod end boots before and even though they are thin they do a good job of keeping the dirt out and grease in. The guy that had them on the front of his F40 Toyota bought the rig with them on it and had no idea who made them. I wouldnt use them in a off road type vehicle but for a street driven vehicle they would work great. I never knew who made them or what they called their product so I did not look for them. Thanks for the link Ralphy. Too bad they only sell the boots with heims. The rubber cup seals are like the ones I made my self out of urathane but they dont seal if their is any misalignment angle involved.

Last edited by tyrellracing (3/05/2012 10:24 pm)

![]() Offline

Offline

My thinking is that the Seals It type may even hold the Heims in a straight position.

The only knowledge I have on them, is that users of this type recommend them. This was again on the Vette Mod board.

Posted by Twin Turbo, owner of the Vette Mod board and racer/builder. "them thar black ones are chinese right? Get some FKs or Auroras w/ teflon wipers and pony up for the seals it seals. The seals it seals dramatically increase the life span of these, the little seals are expensive but they DO WORK!!!"

Last edited by Ralphy (3/06/2012 5:23 am)

![]() Offline

Offline

I use them, Speedway Motors sells them in packs of 10. But if it isn't straight they don't help any. Just a thin rubber lip and easily torn too. But better than nothing, especially if a zerk is fitted. The boots look good, but you'd have to poke a hole in them to use a zerk, or maybe use a needle and fill the boot with grease. Might get messy.

Jim

![]() Offline

Offline

Jim I concur rubber and would be of some use. But, for alignment there are tapered bits to help.

![]() Offline

Offline

For heim seals I made a knife type parting tool and parted conical disks aprox. .080 thick off a large bar of urathane with a engine lathe. These conic disks work great for seals on low angle applications. I was given several large pieces of urathane bushing material that was ordered by mistake with too low of durometer for spring eye bushings. The error wasnt discovered for over a year so return was impossible. They are so soft they bounce like a super ball. Personally I like the full enclosure of the boot design. Subaru has used similar boots on their 4WD HI-LOW linkage that runs externally on their transaxel from the factory. It is too bad the manufacturer of the boots in Ralphys link only sells them with heims and not as a separate product.

![]() Offline

Offline

Jim, I now understand what you mean. I was thinking you were talking about a link rotating. However your talking about the ends not being square to the link. That would be a issue.

![]() Offline

Offline

The image of the long travel Subaru has a Uni ball for the ball joint, not a heim. Uni balls have a higher percentage of surround on ball than a heim. This improvement combined with the way they are designed to be installed with a press fit into a stepped cylindrical bore with a snap ring to ensure it cannot escape. This method of spherical bearing installation will also have the ability to support a much higher axial load through the bore of the ball as well as radial loads. These features make it a good choice for high angle ball joints as long as high misalignment spacers are used. In the image shown, the spacer is the conical post that protrudes from the ball joint.

Last edited by tyrellracing (3/07/2012 2:20 am)

![]() Offline

Offline

The uni ball also has a larger bore than the Johnny Joint vs. the overall diameter.

Here is a Aurora COM-E series. It has a .750 bore, the OD is 1.4375. This size may be useable for the end that has the spring loaded onto it. Using a 3/4" bolt and standing the ball upright. I think you can order these with seals.The Johnny Joint with a 3/4" bolt size has a 3" OD, more than twice the OD. It is a high angle design, however if built right you shouldn't need the high angle.

Specifications

B - Ball Bore

.7500 in

D - Outside Diameter

1.4375 in

H - Race Width

.593 in

W - Ball Width

.750 in

O - Ball Shoulder Diameter

.920 in

M - Chamfer

.044 in

Ball Diameter

1.187 in

a - Misalignment Angle

9 º

Radial Static Limit Load Capacity

47880 lb

Approximate Brg. Weight

.204 lb

Lubrication Options

Question? PTFE liner

COM-E Note

- These bearings not normally stocked - check for availability.

- Ptfe Liners available upon request. Specify by adding suffix "T". Ex.: COM-8ET. (Ptfe Lined spherical bearings have no lubrication holes or groove in race outside diameter.)

Last edited by Ralphy (3/07/2012 4:46 am)

![]() Offline

Offline

Aurora has a pdf file list of racers common ends.

![]() Offline

Offline

This is from a thread about updating control arms on a Kirkham. This is taken from a post directly that Thomas Kirkham made. Post #15

"Rear upper control arm rod end is prone to breaking on a street car. Comp cars used a bigger rod end."

![]() Offline

Offline

Are you saying the Subaru lower arm you posted has a Johnny joint? The Subaru LCA is what I was commenting on last.

![]() Offline

Offline

No, it's a uni ball type.

![]() Offline

Offline

Nice fab work on the Rally car!

![]() Offline

Offline

There is also a spherical mount sealed roller bearing (double Timken) that could be useful on joints that see mainly rotational movement but need to be able to self align. You typically see these in self aligning pillow blocks but the cartridge is removable/replaceable and can be bought separately. I once ground a tool to use in a milling machine boring head to cut the spherical seat and it wasn't too difficult to do. They are available in bores down to around a half inch, so definitely could be adapted to suspension parts, and they aren't too spendy either. The seat has a key slot and you rotate the cartridge 90 degrees to remove or insert it.

Jim

![]() Offline

Offline

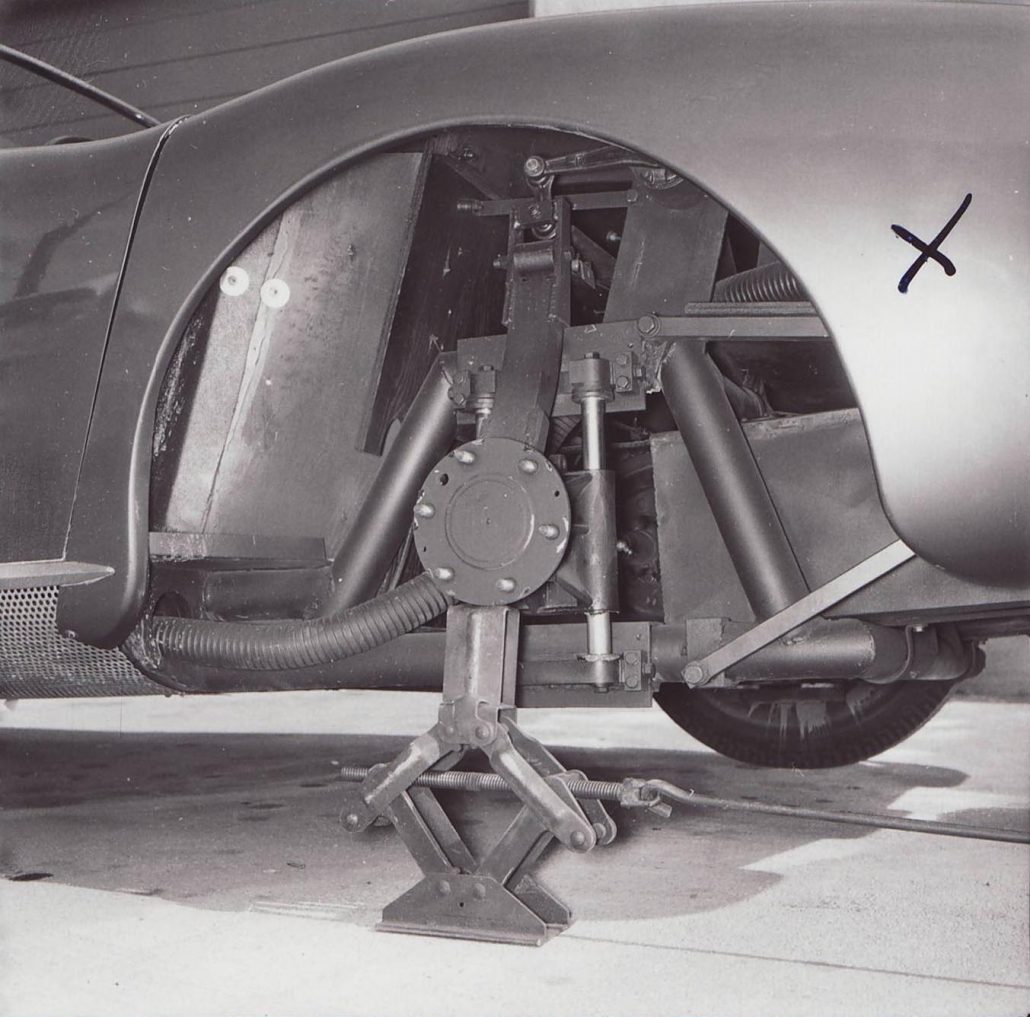

Hoyle in a 1979 MGB fromBritish V8

Hoyle Engineering independent rear suspension, with Ford (Granada) 7.5", 3.36:1 gear ratio and limited slip differential.

![]() Offline

Offline

Here's a good pic of a Kirkham 427 Cobra rear frame.

Last edited by Ralphy (4/11/2012 8:22 pm)

![]() Offline

Offline

Drive Shaft Shop IRS Conversion Kits

Driveshaft Shop Announces The 12-Bolt Hammerhead Diff for the 2010+ Camaro

Video

!

HammerHead Announces Three Stages of 12-Bolt IRS For 2010+ Camaros

First Batch Of Production Camaro HammerHead Castings Off To Machine Shop

HammerHead Nominated Into Foundrymen’s Society Casting of The Year Competition

Other DSS Rear Diff Conversion Kits

Ford 9'' Independent Do it Yourself Kit (Bare Housing / Stubs / Pinion Support)

Kit Cars / Diff Kits / Misc. Parts

Last edited by Ralphy (9/05/2012 9:13 pm)

![]() Offline

Offline

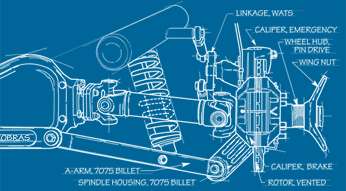

I think I heard about this place in Torrance, California, from Ralphy? When you go to their site you can click on the parts in the suspension and see the parts in living color. Looks like their design was originallly based on Jaguar IRS. Uprights are available with and without Wats linkage.

Last edited by irstang (4/20/2013 1:53 am)

![]() Offline

Offline

Where to put this. Damn, I always wondered about something like this. The upright is on linear slides and appears to have a transverse leaf spring.

Fort Byers Special/TD Mark I Special

"The differential was originally a ’42 Ford, but only the center section was used. Special end plates were fabricated to include the brake mechanism for the inboard rear brakes."

"The chassis design provides a high roll center (16” above ground level) in front and a roll center at ground level in the rear."

Last edited by Ralphy (11/27/2013 4:09 pm)

![]() Offline

Offline

Wow - That is Kinda - different! Use linear bearings for your suspension. Set the camber once, and it never changes. BUT - any chassis roll will be borne only by sidewall flex. Great I suppose for a lakester - or drag racer - not so much a road racer. But, it would have a fairly consistent contact patch.

The article does say:

"...All roll couple is taken from the front. The light unsprung weight of the independent rear suspension and its ability to provide equal torque at both wheels make the car ideal for race course, drag strip, or highway."

Hmmm.

Cheers - Jim

Last edited by phantomjock (12/01/2013 5:39 am)

![]() Offline

Offline

No negative camber gain what so ever? the wheels would lean with the chassis in corners? Because of the wheel leaning with the chassis, positive camber on the outside wheel would be very likely. The linear bearing idea seems like a step backwards. If the car was set up with enough negative camber when static. The inside tire in a corner would have the static neg. camber setting and the body roll combined. The result would be such a small tread patch it wouldnt provide much help in supporting the lateral accelleration. Equal torque applied to the road from the rear tires would depend on the ridgidity of the frame. If it can twist like a cork screw under the engines torque load, All bets are off with the equal torque idea.

![]() Offline

Offline

And with bias ply tires. There's a C3 conversion that gives no camber, it's intened for drag racers. But? The guy says it improves cornering also. Now today's radials have more forgiveness in the sidewall. However?

My thinking was (linear) could it be done in a more modern design? Not fixed at both ends and maybe two different linear shaft mounts, upper and lower?

Or what if the control arms were not arms but fixed like wings? So the forces go into the chassis like a double wishbone. Have the linear shafts mimic the same motion like a double wishbone. Now you've removed the unsprung weight of the control arms. Sounds like an acid trip. lol!

Anyhow I'm really diggin on the Forgotten Fiberglass site!

Ralphy

Last edited by Ralphy (12/02/2013 4:20 pm)

![]() Offline

Offline

Lots of interesting pictures here,

GT6/Spitfire true IRS conversion using the Merkur/Sierra center section.

Looks like it was a success, then dropped out of sight, why?

I'm trying to contact the maker for more info.

![]() Offline

Offline

![]() Offline

Offline

I've gotten his email and have sent him a request to sell me a set of drawings.

Awaiting his response.

![]() Offline

Offline

I've just purchased a '65 Mustang FB for my retirement project car. I'm looking to do an up date and not a restoration. I've been looking at the CTM IRS and like it because of its Ford origins. The brakes and wheels I'd like to use present a potential interference issue with the IRS, the wheels have a 7.2" backspace. Any thoughts on how to work around this issue.

![]() Offline

Offline

Ralphy engine is looking good and also strong

![]() Offline

Offline

Interesting site but wow, so little activity. Anyone here like the new IRS from AME

![]() Offline

Offline

Welcome aboard. Feel free to wake us from our naps, especially with project pics!