|

|

|

|

|

You are not logged in. Would you like to login?

![]() Offline

Offline

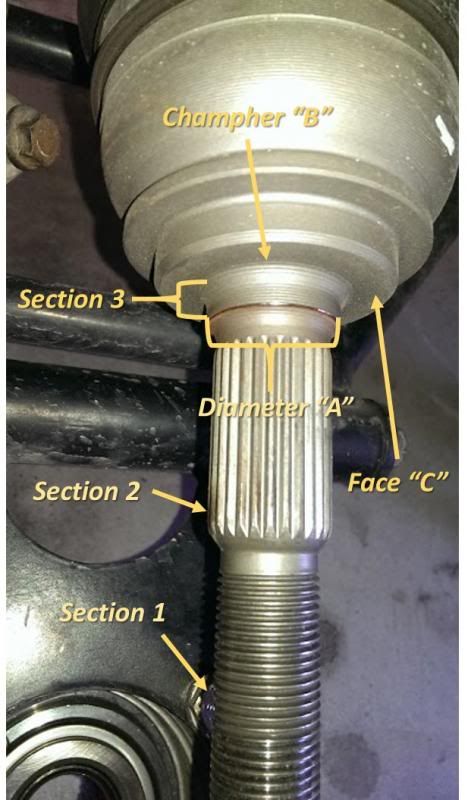

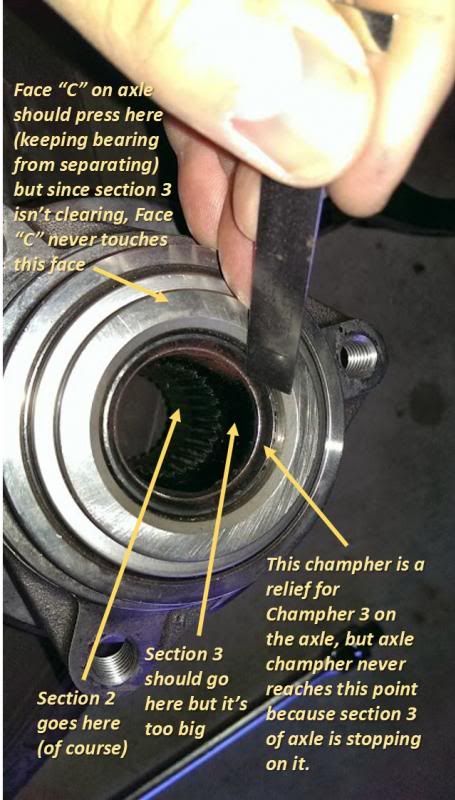

RE: In view #2 is that a gap between the axle and bearing? -- Yes... because section 3 on the axle is too big to fit into the bearing/hub assembly. Pics below may help explain what's going on.

![]() Offline

Offline

I think I finally get what you were trying to tell me Ralphy - if I were to modify just the front portion of section 3 -- effectively making section 3 shorter, that would let the bearing/hub assembly fully seat. I'm wondering if that flat section (section 3) is supposed to be inside the bearing now or not... maybe it's just a bit too long & adjusting that campher would work after all. I don't think I'd want to try & file that area off, so likely still means disassembling the CV to get the stub axle turned on a lathe - just turning down that champher instead of the diameter of section 3 area.

![]() Offline

Offline

Yes, Arrhhhh.....

That to me looks like a boss/diameter the HS should locate on. Does it fit into a bore more than .070 deep? If it doesn't, can your parts be mixed? The bearing being 97 and back. The stub axle, 98 and newer? Maybe you have the wrong bearing for the axle? Who knows what the previous owners did? How the did they drive the car?

To me this looks like a counter bore for your section #3. Point #1 looks like an interference where section #3 starts on your stub axle. Increasing the chamfer will give clearance. Not sure if I'm seeing it right, but that's what I'm seeing/guessing.

Ralphy

Last edited by Ralphy (1/19/2014 4:22 pm)

![]() Offline

Offline

You are right Ralphy. I looked at it some more and the champher in the bearing/hub is jus to clear the transition to section 3. So, I'd just need the stub axle champher trimmed back - a bit more than .070. That was the difference in diameters. I didn't measure it, but the horizontal distance that the bearing is away from the face on the stub axle is more like 1/16". The bearing fits correctly on my old Nissan stub axle so I think that rules out having the wrong bearing. But, it is possible my newer axles are set up for a different year rang S10. Swapping bearing assemblies would definitely be easier than machining the stub axle. With luck the folks where I got the axles will be working tomorrow and I can check.

![]() Offline

Offline

Email the stub axle manufacture a picture and they probably could identify it in a blink of an eye. Something ain't looking right between the two pieces. That may not be a S10 axle.

Ralphy

Last edited by Ralphy (1/19/2014 8:32 pm)

![]() Offline

Offline

R, I'm starting to think you have some "I used a word I shouldn't have" sized stub axles. Since you keep saying it, the bearing fits your Nissan axle. It seems to me the area 3 should slide well up into the bearing. But it's too large in diameter and I think to short. If so, it's not the greatest fix. But if you were to sweat fit a sleeve in front of this area 3 over the splines. Then cut the diameter to fit that bearing, you could get by. I know there's no support in the immediate front of 3. But the bearing should ride up at least a 1/16" or more of the parent/area 3 metal. You pay to ship those parts back and forth to me and I can do it no charge. Where do you live?

I'm pretty sure this is a 97, look at the length of area 3. I also think the new design 98 up, is just as long. And again look at the diameter in area 3, it appears a bit larger.

Edit: Shoot just started thinking later about the axle being heat treated. Hate to cut material off a heat treated part. Hmmm...

Reload again, I don't think area 3 is .070 to large. It's .070 larger than the splines as it should. However that does not mean your press is right. My guess you should have app. .0015 interference. If your bearing has a first bore, measure that bore and then measure area 3 diameter on the axle. If the press is to large, .0025 plus. You can easily spin the stubs on a lathe and polish them in with emory cloth, With no detriment to the axles.

Your bearing should look something like this.

Phew! lol

Ralphy

Last edited by Ralphy (1/20/2014 11:33 am)

![]() Offline

Offline

The Nissan axles were not designed to go with the S10 hub assemblies. They just happen to fit. The back story is that the guy who made the whole IRS on my car had made one for himself. He had an MG and was a Nissan guy so he swapped the turbo charged Nissan motor in and used Nissan IRS components to make his IRS. He wanted to make more and sell them to the MG engine swap crowd (which is a bigger audience than you might think). I wanted an IRS, didn't know how to make it so he and I worked out a deal. Problem was I already had my wheels and they're drilled 5x4.75 and the Nissan hubs couldn't be redrilled to that. So, he did some research and found that a lot of Cobra kit guys used S10 hubs and they happened to use the same diameter & spline the Nissan used. So, he modified his upright design to work with the S10 hubs, narrowed the Nissan and narrowed the Nissan axles. Execution on narrowing the axles wasn't great - weld penetration was only about 3/16" and they weren't sleeved or re-heat treated. Took a few years for me to finish building my car. 2nd time out just test driving in the neighborhood, one of the axles snapped. Wasn't even accelerating hard; just making a left turn pulling away from a stop sign. Looking at the axle pieces was when I realized how they had been narrowed. Considered rewelding and sleeving, but got mixed reviews on how that'd hold up. And, where they were cut meant the weld and sleeve was right in the area the boot is supposed to clamp down.

Talked with the builder but he wasn't prepared to make it right and had lost confidence in him, so bit the bullet and had axles made by "the drive shaft shop". They knew all about the S10 hubs and said they made axles for a lot of racers with them. They are well known and have great reviews so I trust the stub axle is known to work well with the bearing/hub assemblies (more on this in a moment). And, I've found their customer support is awesome. As an example, I mis-measured one side when I gave them the length I needed. Figured I'd have to pay to redo the shaft. But, when I called, they said no problem, just send it back and we'll redo it. Even expedited it for me so I could make a show.

So, back on my fitment issue... I emailed them last night and sent the pictures. Had an email back this morning apologizing, letting me know they were supposed to machine that area, obviously forgot, said they'd send me a return postage label, fix them, and send them back.

If I had more miles on the car with the Nissan axles w/o bearing failure, I would have suspected the new axles right away. But, since I didn't, and I had more confidence in the driveshaft shop than the IRS builder, I suspected something in the design and didn't look close enough earlier!

Lesson learned on that one.

![]() Offline

Offline

That's fantastic you found the fix. It's also bang up of, The Driveshaft Shop.

That's a new one to me that Cobra guys are using S10 parts and design. I'm on Club Cobra quit often. Now I'm wondering which manufacture is going that route.

Ralphy

Last edited by Ralphy (1/20/2014 12:18 pm)

![]() Offline

Offline

Well, my IRS was designed and built 8 or 9 years ago. I don't think Factory 5 or anyone else was making an IRS for them at the time so it was probably the brave souls who paved the way (or at least broke the ice) for the manufacturers to realize the market was ready.