|

|

|

|

|

You are not logged in. Would you like to login?

1 of 1

1 of 1

![]() Offline

Offline

Most muscle-cars and pony-cars enthusiasts agree that the Mumford linkage is the best handling live-axle suspension ever.

Some even say that it's better than many double wishbone suspensions, at least in smooth pavement. Leaving the "better than IRS" debate aside, most agree its incredible.

There's something I just dont get about its geometry:

It looks like when the body rolls the whole axle moves a little bit to the INSIDE of the corner. It sound logical that you would like the axle to move to the OUTSIDE as to get slightly more track width on the heavily loaded outside tires, where it matters the most.

I even built a small cardboard model to check its geometry.

What puzzles me is that you can get a really low roll center while avoiding the axle sideways movement mentioned above, by using a much simpler 3 link trailing arm system.

So it looks like the lateral axle movement is intentional and actually HELPS handling?

Or maybe the sideways movement slight disadvantage is minimal compared to its optimal roll center location?

I must admit I don't know much about optimal roll centers location, much less how their sideways movement affect handling.

Help please! I'm confused

Thanks.

![]() Offline

Offline

First -

Thanks heaps for posting that "all known about MUMFORD linkage - Link. A lot to digest there. EVen though I'm not Live axle - but dual wishbone -- always looking.

Cheers - Jim

Last edited by phantomjock (4/06/2013 3:01 pm)

![]() Offline

Offline

And now that I've gone back and read Mark Savitske's points:

I'm wondering about my double wiashbone -- having been on the track of low ground clearance and aero underbody, etc....

Oh well, as Colin Chapman said. " Any suspension will do the job --- as long as you don't let it work!"

Cheers - Jim

![]() Offline

Offline

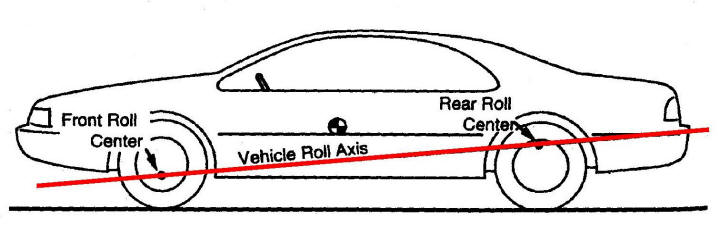

Going back to what irstang mentioned some time ago, RC Axis should be lower to the end of the vehical that is the heaviest. I would say hmmm... Add to what PJ mentioned above. Plus if you look at the trailing links they are of the common outboard type, So the anti-squat/anti-dive is variable. Which goes away with the double-wishbone. To sumerize, the double-wishbone upsets the handling least when accelerating and braking in corners. Also there's the unsprung weight issue.

Thanks for the teaser coolrod. Please keep posting!

Ralphy

Last edited by Ralphy (4/07/2013 5:27 am)

![]() Offline

Offline

Hi Ralphy, I don't recall coming to the conclusion that roll axis inclination "should be lower to the end of the vehicle that is the heaviest". When I started the topic on roll axis inclination I was in doubt as to which way the inclination should be set up. Tyrellracing gives a good explanation of how an inclination to the front makes a car more predictable as it approachs oversteer. After discussion I concluded that the roll center at the rear, for my application with independent suspension, should be slightly higher at the rear. When you say hmmm, I think you may be thinking of what happens to a rear engine race car with with more weight at the rear? Fuel for another topic?

The Mumford link looks like it would control lateral movement while acting like a really stiff ant-sway bar.

![]() Offline

Offline

Maybe I misspoke or misunderstand. If I remember a conversation about my car being 50/50 weight bias, and my roll axis inclination being level?

Ralphy

![]() Offline

Offline

No harm, no foul. I know you and I have studied and read articles about balancing the front and rear of a race car using roll angle analysis. With a 50/50 weight distribution you very well may end up with no roll axis inclination. The question is; will this make the car loose and possibly oversteer without warning?

![]() Offline

Offline

I found some info in my free time at work. Okay, down to the front supports under steer and the more level loosens the rear. Seems faint, it's been awhile, but. Yeah we discussed that, I think. LOL! I saw a pic that states the Corvette has no angle. Sorry if this seams fragmented, a little burned out from work.

Ralphy

Last edited by Ralphy (4/08/2013 5:25 pm)

![]() Offline

Offline

I haven't seen anyone address the OP's original observation about the mumford causing the axle to shift, is this true and/or a concern?

![]() Offline

Offline

The answer depends on how well you design the linkage, bellcranks and their locations. Design intent of the Mumford was to eliminate lateral movement. One would have to model this on paper or in CAD and look at bump, roll, ground clearance, and roll center. There is a risk of binding with the Mumford but it should control lateral movement better than a panhard bar.

1 of 1

1 of 1