|

|

|

|

|

You are not logged in. Would you like to login?

![]() Offline

Offline

Hi Guys, Great forum!

Just got a few questions im hoping you guys might be able to answer,

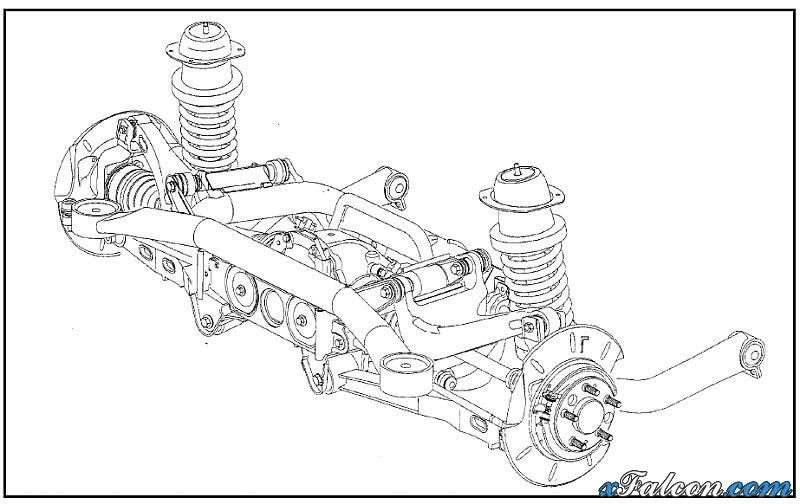

Ive been working on my project car for a few years now (1987 Ford Falcon), and am working on getting IRS into the rear. Initally i wanted to use Late model falcon IRS, here in OZ ford Ford designed an IRS in conjuction with BTR to bolt into there falcons as an option, utilising the original control arm mountings with the addition of rear mountings welded to the chassis rails. It look really easy to graft into my older falcon as a lot of the rear architecture is the same. But ive since changed my mind as the whole assembly is ridiculously heavy, with forged steel control arms, tubular frame etc, I like it, and installation would be pretty easy, even the springs bolts straight up into the factory towers, the only fabrication required would be the rear mountings, but its heavy and a little complicated.

so that leads me to the jag rear end, which is so simple, and obviously effective being used in so many street rods and kit cars over the years. Now the only tricky bit to my install is the want for airbag suspension, Ive bagged the front end, which was pretty easy using a shockwave kit from ridetech, our falcons ran suspension based on the early falcons and mustangs right up to 1987 beleive it or not so i was able to utilise the mustang kit.

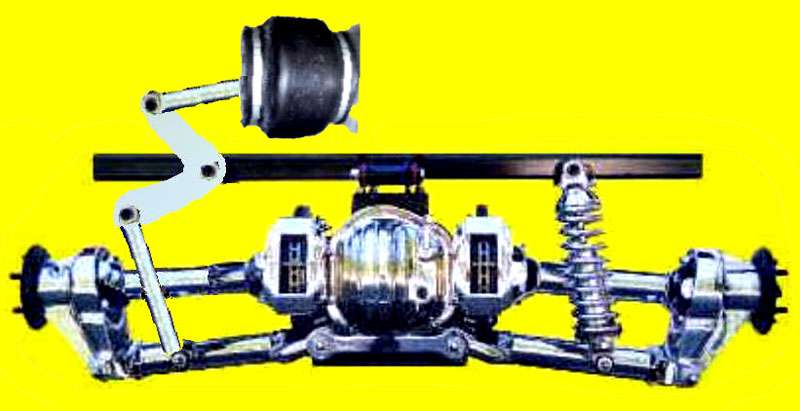

for the rear ive been thinking hard about how im going to run bags. My first thought was to run 4 7000 series shockwaves, but it just gets to expensive. Next option was to use some bags with external shocks (the traditional bag method) much like this guy, But id probably use a pair of shockwaves and try and get the leverage ratio a little better

The cage he has built look greatand is similar to what i had in mind, id also utilise the factory lower control arm mounts as another pickup point for the IRS Cage much like ford did in the first line draawing i posted.

Now I havent actually purchased a jag rear end yet im not sure whats going to work, if clearence is tight i thought maybe some canterlevers and some shockwaves in the trunk may be the answer....

anyone got any pictures handy of bagged Jag IRS?

Another question i had, do you have to use strut rods to support the jags lower arms? They look like really decent bits of gear with the pivots spread out over a resonably wide area, if the lower arms were triangulated is there really any need for additional support for the lower arms? Looking at the jag setup in a jaguar they ran lower arms with big flexable bushings, which kind of indicated they really dont support the arms but keep the cage from moving around? They also run in a straight line, which is completly wrong if there used to actually support the lower arms, they look as if there intentionally designed to move the cage back in fourth slightly under suspension movment? what am i missing? I dont get the idea behind jags lower forward mounted arms.

With our falcons, and probably most live axle cars it also occured to me that one axle is shorter than the other because of the offset pinion. How will this effect an IRS install? I pressume a jag diff centre needs to sit slightly off centre in relation the the vehicles centreline, because Im pressuming the half shafts and lower arms would be identical lengths so camber change and suspension charectersitics stay the same from left to right, Does this mean the the tailshaft will sit off to the side slightly? How will this effect Driveshaft vibration?? How far off centre will the pinion sit? Or am i completly wrong on this?

Gareth

Last edited by KLR250 (4/23/2011 6:59 pm)

![]() Offline

Offline

First of all let me say welcome to the forum!!! I would have gotten back to you yesterday but I knew there were some pictures out there of a bagged IRS and I was trying to find it.

This is an interesting Jag rear end. There are things I like about the way they did it and there some things I do not like.

First I do not like the fact that they used the OEM jag wish bones to mount the air bag set up to. The fabricator who put that together obviously has some skills and they could have easily made custom lowers that incorporate the bag mount. I would recommend something similar in your project if you decide to mount it like that. the second issue I see is the actual bag mount location. I like the idea of using the OEM mounts and a lever system at the top pivot so that you can mount the air bags above. I found this photoshopped picture when I did a search for Jag rear and air bags and it gives a rough idea of what I am talking about.

Here are some other pictures (the onesI knew I had seen but was having a hard time finding) its a t-bird IRS rather than a Jag but the technique could easily apply to both.

The trailing arms have several purposes. one is to reduce the load on the inner pivots when starting and stopping and also I have herd speculation that they are there to "squat" the suspension during launches. I chose to make mine rigidly mounted which required moving the front pivot in line with the inner pivots of the wish bones.

The pinion question is a whole other discussion. some will tell you it does not matter because the differential is hard mounted others swear by the fact that you must have things lined up with in one degree or you will have nothing but problems. I am of the mind that these are the two extremes and the truth lies some where in the middle. As to your question of the offset of the pinion the biggest thing to consider is that the pinion and transmission are parallel on all planes. not pointing at each other but parallel. As long as the transmission is parallel with the chassis, the pinion is parallel with the chassis, AND the angle up of the pinion is parallel with the angle down of the transmission that the u-joint will function as designed with no issue or premature where. make sense??

Once agin welcome to the forum I look forward to hearing more about and seeing some pix of your project.

![]() Offline

Offline

Thanks very m,uch for the reply, and also for finding those pictures! The lever system is kind of what i had in mind, My idea was very similar to this, except i would make a type of tubular wishbone to go around the drive shafts and hook to the factory coilover mounting points, with a pushrod up through the factory shock tower in the car to a lever

Im going to look at a XJ6 series 2 Jag rear end on wednesday, Cant wait to get one jacked up and sitting in place so i can see what options are available

Gareth

Last edited by KLR250 (4/24/2011 2:23 pm)

![]() Offline

Offline

Heres som Slide show Vids of my project. The slide shows are a fair way behind what im actually up to, and the sound tracks may irritate some lol But i like em hehe

![]() Offline

Offline

Vibration from the driveshaft is caused from mismatched angles of U-joints. Running from the side is not an issue. Universal joints accelerate and decelerate through rotation. At the shaft as Daze says the trans output and pinion need to be parallel, then the U-joints need to be equal angle regardless of direction. The greater the angle of the joint the greater the acceleration deceleration. Why have U-joints equal? Because one is opposite the other, one cancels the others speed change. It's also suggested a 3 degree angle. this angle allows the needle bearings to rotate and wear evenly vs. the bearings being stationary at 0 degree. Causing the bearings to wear into one point, power wise 0 degree would allow maximum HP through the driveshaft.

"A configuration known as a double Cardan joint drive shaft partially overcomes the problem of jerky rotation. This configuration uses two U-joints joined by an intermediate shaft, with the second U-joint phased in relation to the first U-joint to cancel the changing angular velocity. In this configuration, the angular velocity of the driven shaft will match that of the driving shaft, provided that both the driving shaft and the driven shaft are at equal angles with respect to the intermediate shaft (but not necessarily in the same plane) and that the two universal joints are 90 degrees out of phase. This assembly is commonly employed in rear wheel drive vehicles, where it is known as a drive shaft or propeller (prop) shaft."

As far as the OZ Ford design, it removes the halfshaft as a link. Using the half shaft as a link such as Jag and the early Corvette. Causes more wear due to loading on the universals and carrier. Not knowing the Jag as well as Daze, but as I have read doing a brake job sucks and for performance/racing , Guys move the brakes outboard for ease of change and cooling. Inboard brakes run hotter.

Last edited by Ralphy (4/24/2011 7:04 pm)

![]() Offline

Offline

Thanks for the reply there Ralphy!

On paper the ford IRS is a great bit of gear, Im really stuck at a crossroads of which direction to go in. Im almost sold on the Jag IRS, but a few things do bother me, inboard brakes are not my cup of tea, especially with the open style rims ill be running, it will look kind of strange not seeing a disc and calliper there. The other issue is suspension travel, the jag rear really doesnt appear to have that much travel, and with the bags im worried about binding universals. The ford setup obviously employs CV joints. The ford setup will go in a lot easier with less fabirication, but the weight of the unit is my main argument against it. The thought did cross my mind to make some tubular style arms to overcome some weight problems, as the factory arms are of forged steel, there really heavy bits of gear. Things like diff ratios, LSD centres and replacment parts are really common. The only other concern with the ford unit its the hub bearings, They seem to be a real pain in the arse to get out once they stuff up, with people damaging the hubs trying to replace them. Like i said earlier im going to look at a Jag IRS on wednesday, so ill see how i feel once i see the unit, take some measurments and get more familiar with them

![]() Offline

Offline

Well, a carrier is a carrier. Strip everything else away and all the third members work the same. Maybe you need to build your setup from scratch. It's been done. To me it sounds like your going in the wrong direction with an IRS for a couple of reasons, first of all your halfshafts should be straight, no angle when parked. You start raising and lowering the car and it messes up your camber. Another is your statement about launching. Coming of the line with an IRS hard is not a trait that an IRS shines at. When your car squats again camber changes will prevent itself from a flat tire patch. Drag Vette designed a setup that removes the camber through suspension travel by moving the camber rod and adding an upper. Then shortening the halfshafts about 1/2" and allowing the spindle to slide in and out. If your looking for distance of travel I would think you need to use a unit with the shocks being as close to vertical as possible.

Last edited by Ralphy (4/25/2011 6:37 am)

![]() Offline

Offline

I get 8" of travel. I also centered the diff, which gives a different length on the arms +- 5/8". A fabricated LCA with an additional forward pivot will have room for an air bag platform, and properly designed will have no twisting motion.

It is not necessary to have the same length of arms on both sides. The driver does not sit in the middle of the car anyway.

JB

![]() Offline

Offline

Ralphy wrote:

Well, a carrier is a carrier. Strip everything else away and all the third members work the same. Maybe you need to build your setup from scratch. It's been done. To me it sounds like your going in the wrong direction with an IRS for a couple of reasons, first of all your halfshafts should be straight, no angle when parked. You start raising and lowering the car and it messes up your camber. Another is your statement about launching. Coming of the line with an IRS hard is not a trait that an IRS shines at. When your car squats again camber changes will prevent itself from a flat tire patch. Drag Vette designed a setup that removes the camber through suspension travel by moving the camber rod and adding an upper. Then shortening the halfshafts about 1/2" and allowing the spindle to slide in and out. If your looking for distance of travel I would think you need to use a unit with the shocks being as close to vertical as possible.

I have considered a sctratch built setup, but my skill set is not good enough at this stage unfortunatly. I probably am going in the wrong direction with IRS, Theres only one reason i want to use it in my car, Wow Factor lol

the car will never be a drag car, more a cruiser with a bit of power when i put the foot down. I will never cruise around with the car slammed, and i will be using ride height sensors and controller from accuair, so i suppose after thinking about it some more travel isnt going to be a major concern, As ive also lost a little bit of travel with the shockwave bags up front.

![]() Offline

Offline

Ralphy wrote:

"A configuration known as a double Cardan joint drive shaft partially overcomes the problem of jerky rotation. This configuration uses two U-joints joined by an intermediate shaft, with the second U-joint phased in relation to the first U-joint to cancel the changing angular velocity. In this configuration, the angular velocity of the driven shaft will match that of the driving shaft, provided that both the driving shaft and the driven shaft are at equal angles with respect to the intermediate shaft (but not necessarily in the same plane) and that the two universal joints are 90 degrees out of phase. This assembly is commonly employed in rear wheel drive vehicles, where it is known as a drive shaft or propeller (prop) shaft."

Thats all good information but I have one thing to add. in order for it to work properly the third u-joint, the one in single cardan requires the drive shaft to be perfectly in line with what ever the single cardan joint is mounted to. in other words if the double is at the pinion the drive shaft must be in line with the transmission. the reason for this is the single u-joint does not have anything to cancel out it speed changes so it needs to be moving at a constant speed.

![]() Offline

Offline

KLR250 wrote:

Thanks for the reply there Ralphy!

but a few things do bother me, inboard brakes are not my cup of tea, especially with the open style rims ill be running, it will look kind of strange not seeing a disc and calliper there.

easy fix mount them out board. if you get the hubs and half shafts from a an xj40, x 300 or x308 you can easily mount the brakes at the hub.

from original IRS forum, Daze wrote:

OK I learned a lot. I got a set of X308 or 99 XJ8 hubs and half shafts asI could not find any XJ40 or X300 parts. There are some things that will be a little harder to overcome than others. From behind the only main differences are the brake cable and the splash shield.

From the front there are some noticeable differences, the biggest of which is the the integrated parking brake. This poses one major issue, it requires the specific Jaguar rotor and there is an adjustment hole drilled in the hub. These two things make re-drilling the hub out of the question so bolt pattern adapters will need to be used

According to the info I had the XJ40 hubs require a spacer between them and the wish bone because the XJ40 hub is slightly narrower, but when I fit the hub in to the wish bone it was a nice tight fit. The pins however are a different size so I will either have to bore out the the bearing sleeve by .050 to accept the XJ6 pin, or machine some UHMW bushings to fit in the hub and accept the bigger shaft. I am leaning toward the second option

The half shafts are the exact same length as the XJ6 units but unlike the info I had that said the u-joints are the same, they are actually different. the cap size is the same but the width of the u-joint is about 1/2" smaller. good news is I will be able to use the new half shafts in their entirety.

![]() Offline

Offline

wow, that really gives some options! Thanks for posting that up

![]() Offline

Offline

Thats why the forum is here ![]()

![]() just weight we will start giving you ideas and then you will be wanting stuff you didn't even know you wanted ;)

just weight we will start giving you ideas and then you will be wanting stuff you didn't even know you wanted ;)

![]() Offline

Offline

Hi Guys,

After spending heaps of time on wednesday looking at Jag IRS units im pretty much sold on them. I found a Local guy who has 13 61" units,! he bought them all off a guy who was getting out of the custom car game, I have to go and see him next week, as he was a bit busy and had to work out a price. The great news is, apparently plenty of jags came out with power lock over here, he had two sitting in his workshop, one of which he was fitting in between some 32 ford rails. He also suggested using the cage, but its butt ugly and all the wrong shape for between my rails, he solid mounts his, but mentioned how well the jag 4 wheel steer really works, which kind of got me thinking (I think to much)

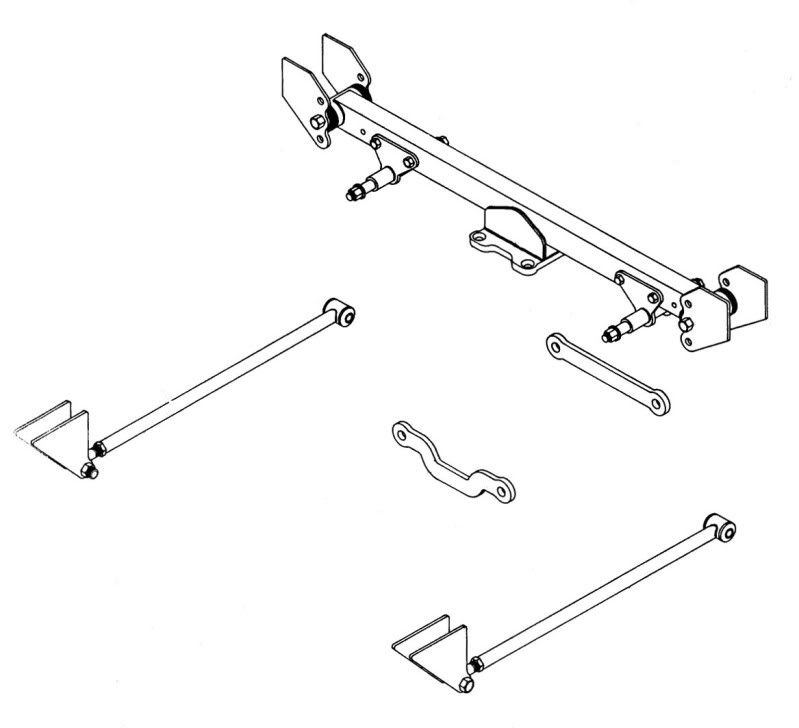

I found this drawing on jalopy journal, it works pretty much like the jag design, but much cleaner, and tighter. The front pivot on the trailing arms would be a rose joint or a tie rod end maybe?? whilst the bush on the jags control arm would be a urethane one.....I suppose the key would be to keep the trailing arms the same length as the original jag ones?

the bushings used on the diff crossmember would probably be better if they were rubber to allow less binding movement

im not so keen on running the trailing arms inboard simply because i have 2 3" exhaust pipes to snake through the area, and having another crossmember up there for that is really going to take away lots of space

anyways, food for thought maybe

opinions?

Gareth

Last edited by KLR250 (4/29/2011 5:03 pm)

![]() Offline

Offline

everybody like pictures ;)

anyway, heres where it will go, tons of room once i drill out the watts link bracketry spot welds and remove it all

unfortunatly i prepped and painted everything (before the IRS plans and stmbling across Dazecars.......damn it lol)

now ill be getting the welder and cutting discs out ![]()

my shiny newish mig is about to get a work out

bye bye live axle

Im thinking, after all these weirdos do unboxing Videos on youtube, maybe ill do a jaguar uncaging video!! haha

Gareth

Last edited by KLR250 (4/29/2011 5:22 pm)

![]() Offline

Offline

KLR250 wrote:

(I think to much)

welcome to the club, I spend almost as much time building things in my head as do in my shop. I live for the design, in fact I have been known to put a project away for a wile once I have worked all the bugs out. ![]()

KLR250 wrote:

Hi Guys,

The great news is, apparently plenty of jags came out with power lock over here, he had two sitting in his workshop, one of which he was fitting in between some 32 ford rails.

if you can get one with a LS diff for about the same price as an open diff, do it, but keep in mind that there are more options if you go to dana internals. there are not only more options, but parts are also easier to come by.

KLR250 wrote:

I found this drawing on jalopy journal, it works pretty much like the jag design, but much cleaner, and tighter. The front pivot on the trailing arms would be a rose joint or a tie rod end maybe?? whilst the bush on the jags control arm would be a urethane one.....I suppose the key would be to keep the trailing arms the same length as the original jag ones?

Looks like a good drawing a if you hadn't said otherwise I would have assumed it was designed specifically for the jag unit. with the trailing arms as drawn they will still bind because the arms will be on different arcs. if you are going to do it that way one end needs to have a rubber bushing and it needs to be fairly large to absorb the differences between the arcs.

KLR250 wrote:

everybody like pictures ;)

I LOVE pictures!!! thanks for posting them. it looks like you have put a lot of work in to that car I can't weight to see how the project progresses.

![]() Offline

Offline

Im wondering weather anyone could get some measurments on an unmodified jag rear end from the wide 61" unit. Because every unit i look at is in a factory cage with springs i cant get some measurments im chasing.

Im after the distance between the trailing arm pivot on each wishbone i.e centre to centre from one side to to the other when the lower wishbones are level

also i need the lower spring pivot centre to centre from one side to the other, again whilst the lower wishbones are level

Im also after the trailing arm length of the factory jag arm?

If anyone can supply me with these dimensions id really appreciate the efforts

Regards, Gareth

![]() Offline

Offline

I should be able to get those measurements for you today.

![]() Offline

Offline

If you could do that id really appreciate it

Thanks very much in advance

Gareth

![]() Offline

Offline

your measurements are as follows, but Keep in mind there is no place to easily secure a tape so the measurements might be off 1/8" or so

first of all the stock unit out of an XJ6 61.75" hub to hub when the wish bones are level, not 61"

trailing arm pivot on the DS to the PS center to center is 44"

springs center to center 37.5"

factory jag arm is 19.25" long 16.5" center to center with the bigger flat bushing having a diameter of 3.5" and the smaller wish bone bushing having a diameter of 2"

Let me know if I can help further

![]() Offline

Offline

Daze wrote:

your measurements are as follows, but Keep in mind there is no place to easily secure a tape so the measurements might be off 1/8" or so

first of all the stock unit out of an XJ6 61.75" hub to hub when the wish bones are level, not 61"

trailing arm pivot on the DS to the PS center to center is 44"

springs center to center 37.5"

factory jag arm is 19.25" long 16.5" center to center with the bigger flat bushing having a diameter of 3.5" and the smaller wish bone bushing having a diameter of 2"

Let me know if I can help further

your a life saver Daze, Thankyou very much! owe ya one

Gareth

![]() Offline

Offline

okay, been measuring bits n peices, just a few comparison

My falcon diff is 61.26" vs jag 61.75", spot on or close enough to

lower control arm pivots (one side to the other)

Falcon 45.27"

Jag 44"

again, really close

Spring spacing from one side to the other

Jag 37.5"

Ford 40.95"

lower control arm length center to centre

Jag 16.5"

ford 25.8"

so if i plan to mount it as per the jag design the longer arms maybe a good thing with a little less angular change

so far everything seem to look good if i want to run suspension pushrods onto canterlevers inside the trunk

out of interest, whats the wheel spigot diameter on the jag hubs?

and one last thing, jaguar drive shaft flange, whats the hole spacing?

both of these are just trivial for interests sake, im not to concerned what they are

Last edited by KLR250 (5/06/2011 7:11 pm)