|

|

|

|

|

You are not logged in. Would you like to login?

![]() Offline

Offline

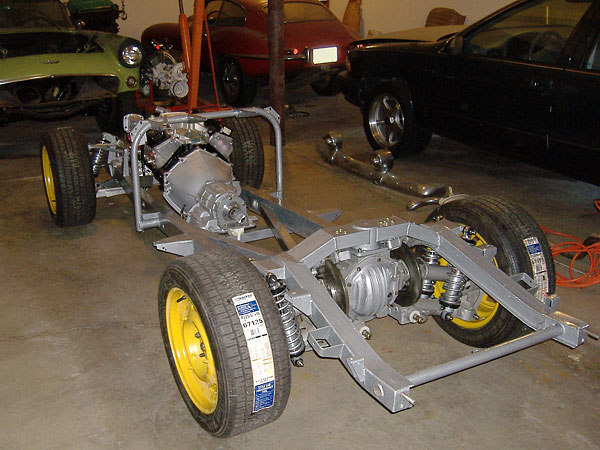

Jaguar XJ6 IRS in a 1964.5 Mustang

IRS unit as it came to me

some tare down pix

wishbone narrowing jig

limited slip carrier install

OEM Mustang rear

removed rear

hub rebuild

side arms sub structure

subframe mock up

notching sub frame for brake calipers

first mock up

checking spring rate

assembled sub frame

more recent mock up

Last edited by Daze (12/30/2011 10:02 pm)

![]() Offline

Offline

I hope Im doing this right. What I'm starting with.

This is what Im sticking it in.

Here are some pics that sorta show how Im going with it.

I have been working on the engine and trans mounts for awhile and I think I have them nailed down now so went back to the RA sub framing. Going with a frame wrap so I can drop the whole thing with a few bolts.

Going to try isolating by using bushings in the ends of the main X that will be solid to the RA. Havent got them yet (ordered). So for now this is where I am.

Slow progress

Borrowed a tire/wheel pretty close to what Im going for to help mock up.

Last edited by Digz (2/12/2012 7:41 am)

![]() Offline

Offline

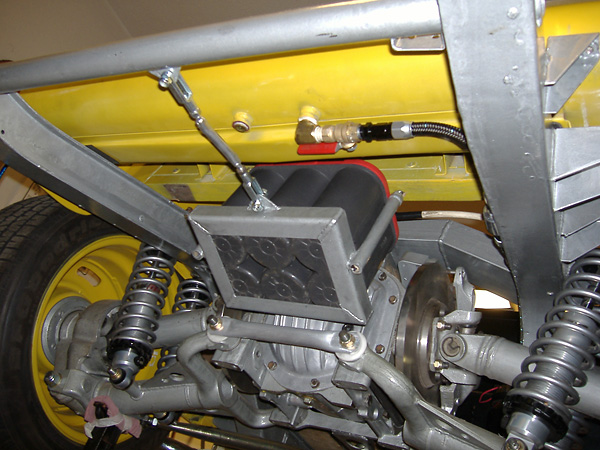

1952 MG TD V8

Last edited by Ralphy (12/21/2011 9:05 am)

![]() Offline

Offline

Jag with aftermarket LCA on a Cobra kit

Last edited by Ralphy (1/05/2012 6:37 pm)

![]() Offline

Offline

This will make Day go crazy!

Last edited by Ralphy (12/30/2011 2:39 pm)

![]() Offline

Offline

Ralphy wrote:

1952 MG TD V8

That is so creative to put the battery there! Is it hard to remove it? I will have to look at my Jaguar to see if there are spaces like that available as I am putting a crazy mobile office with dual batteries so if I can place a battery not in the trunk that would be so cool; PS there is likely no room in the engine bay as the big v8 appears to suck up all of the space in the Jaguar 3.8s?

![]() Offline

Offline

I'm looking at running a dry cell and putting it underneath also. So I would also have some reachable battery posts.

Home made aluminum LCA in a T Bucket

Last edited by Ralphy (12/30/2011 2:38 pm)

![]() Offline

Offline

ERA AC Cobra

Last edited by Ralphy (12/30/2011 2:37 pm)

![]() Offline

Offline

Jaguar IRS in a Datsun 510

WOW, NARROW!

Last edited by Ralphy (12/30/2011 2:37 pm)

![]() Offline

Offline

Came across the other Watts Link video I had seen before. Arntz Buttler AC Cobra

Video

Link to thread

Mickmates Watts Link video on a Contemporary AC Cobra

Last edited by Ralphy (1/12/2012 12:54 pm)

![]() Offline

Offline

MGB Roadmaster Status Report (aka "Project BADASS")

OK You Jag Lovers, 81 Pages Of Reading On This Build

,166,page=1

Last edited by Ralphy (1/12/2012 12:36 pm)

![]() Offline

Offline

Notice anything funny about that picture?

![]() Offline

Offline

I give.

![]() Offline

Offline

Ralphy wrote:

Jaguar IRS in a Datsun 510

WOW, NARROW!

Even if you accept the premise of the big giant rear meat being tucked in so far, I see a lot I'd have done very differently.

![]() Offline

Offline

Jim Blackwood wrote:

Notice anything funny about that picture?

Yes, the photo is upside down! (trick photogrphy)

![]() Offline

Offline

I just noticed he went so narrow, the top shock mount is outside the lower. WOW!

JEM wrote:

Ralphy wrote:

Jaguar IRS in a Datsun 510

WOW, NARROW!Even if you accept the premise of the big giant rear meat being tucked in so far, I see a lot I'd have done very differently.

![]() Offline

Offline

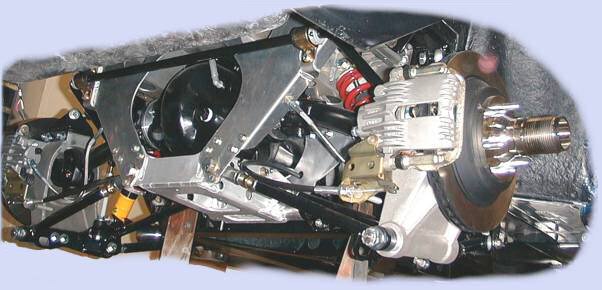

AC Cobra Chassis

![]() Offline

Offline

Ralphy wrote:

I just noticed he went so narrow, the top shock mount is outside the lower. WOW!

There's that, and I'm wondering just what he thinks he gets from carrying that much rear rubber, and running double spring/shock coilovers in a car that small and light with arms that short is just a complete waste IMO, but the real problem...how's the effin' diff mounted?

Let's review how the diff's mounted in an XJ - it's rigidly mounted to the cage at the top and the bottom. The cage is then mounted to the car through rubber bushings at the outer ends (nice long lateral lever 'tween diff and cage ends) and acceleration/braking torque is passed through the lower arms to the trailing arms to the body. The cage mounts also carry the vehicle weight 'cause the coilovers mount to the cage.

In the XJ40 Jag took off the trailing arms, and revised the diff mounting, it now sits on a cradle that mounts to the body with two fairly widely-spaced rubber mounts in the rear and two large and widely-spaced mounts up front. Further, these now handle only fore/aft and lateral loads - the vehicle weight is now passed up to the fender structure, not through the diff mount.

His design has the diff carried by a couple bushings at the top. Solid (noise) or rubber (flex)? Can't tell. His 'front pinion mounts' are little rod-end things that go straight up and down - yeah, they'll keep the nose of the diff from bobbing up and down, but they won't provide too much help in keeping it from moving front/rear. I see no other support for the bottom of the diff.

I'm fairly confident that no matter what his upper diff mount looks like it's going to move around enough for this to matter, even if it's solid it'll still twist everything a bit if he's got any torque at all.

So acceleration/braking loads are going to go through his lower radius rods - it's going to push straight forward on them under acceleration and pull straight back on them under braking. That's what the stock XJ setup does, except the XJ has a little compliance built in here and there.

Cornering loads are the same story. The diff's going to swing side-to-side on its upper mount (in the stock XJ setup the cage prevents this), the little front links will offer minimal resistance, and mostly it's just going to be a triangle twisting at those front links. One side pushes forward, the other side pulls back.

Notice how the rod ends are mounted on the fronts of those arms. He'd designed them as if all the loads on them will be purely lateral loads, but my guess is that most of the force on them will be pushing against the sides of the rod ends. Not good.

He's also tossed all the bearings in favor of a bunch of nylon bushings, more friction, more wear, and more slop than Jag's expensive roller bearings.

IMO he should have come up with a better lower mount for the diff case, kept the roller bearings, and dumped the radius arms entirely. And, of course, used a single spring/shock.

Last edited by JEM (1/17/2012 1:27 pm)

![]() Offline

Offline

Had to get on the right laptop before I could post these:

Jim

![]() Offline

Offline

JEM.

I remember this guy now at CC. He is to run two coilovers. Maybe he could have also stood the coilover straighter and outward. I totally agree, housing is just hanging. Look at how well he fastens the upper coilovers. Then check out his trailing link. Some of his issues were addressed on a thread at CC. I just noticed the upper coilover mount can be moved up or down, minimal but that's cool!

Here's the thread.

Hey Jim Blackwood can you give a link to those pix?

Last edited by Ralphy (1/18/2012 12:07 pm)

![]() Offline

Offline

Ralphy, I think most of the photos are in this thread:

,274

Mostly on pages 8 and 9.

The big advantage is that the XJS unit only needed narrowed 5-1/4" IIRC. I used wheels with a 40mm neg. offset, moving the uprights well inside the rim. Of course that means 17" rims, although some 16's would work.

On the front. -25mm offset was used, again, moving the steering knuckle inside the rim but keeping steering forces low with a 255 tire. (rears are 315).

The entire unit is a "bolt-in" using the stock ox-cart suspension mount points.

Jim

Last edited by Jim Blackwood (1/18/2012 1:03 pm)

![]() Offline

Offline

Jim B, LOL! I forget about your Avatar. I have wandered over your build more than once. British V8's has got to be one of my favorite sites.

Ralphy

![]() Offline

Offline

Jag IRS in a Cobra kit

Last edited by Ralphy (1/30/2012 11:54 am)

![]() Offline

Offline

A guy on the van forum found this. I dont have a link to the build. perhaps british V8s? Im not even sure what it is in.

Has to be the narrowest of any of the pics I have seen. And I'm curious as to how they hold it off the ground.

![]() Offline

Offline

That's pretty narrow Digz.

Another Jag IRS in a Cobra Kit, with the upper Watts Link. Pin drive wheels/knock offs

Last edited by Ralphy (1/31/2012 7:26 am)

![]() Offline

Offline

Digz wrote:

And I'm curious as to how they hold it off the ground.

Don't you see the wood blocks? ;)

Could be they used a coilover or something to the trailing-arm pickup, the arms have been shorn of their normal lower shock-mounts but the trailing-arm mount is still there.

![]() Offline

Offline

Your being plugged at Club Cobra Day!

Rebel1 Rebel1 is offline

CC Member

Visit my Photo Gallery

Join Date: May 2002

Location: Brisbane Australia, QLD

Cobra Make, Engine: RMC under re-construction, GenIV with tremec 600, Jag 3.31 L/S diff

Posts: 3,184

Rank Up Rank Down Not Ranked

Default

With regard to servicing the Jag center you should be aware of this info:

DazeCars, Mustang IRS or Independent Rear Suspension page IV

With regard to shortening and other info then go here:

Independent Rear Suspension Forum / The Jaguar IRS picture thread

and here:

DazeCars, Mustang IRS or Independent Rear Suspension page III

With regard to other info re IRS then choose a thread from here:

Independent Rear Suspension Forum / Independent Rear Suspension Forum

__________________

Brisbane Australia:

Beautiful one day, perfect the next.

Last edited by Ralphy (2/20/2012 11:33 pm)

![]() Offline

Offline

Affinity Imports

Parts

![]() Offline

Offline

Some UK Pics

Parts

For JAG I.R.S.

Manufactured from mirror polished stainless steel to accept all Jaguar bearings and

seals to fit standard Jaguar bottom wishbone.

Last edited by Ralphy (3/13/2012 4:08 am)

![]() Offline

Offline

So Ralphy. Have you accually installed an IRS in anything yet or is this just more of your pipe dream. Your kit car copy of a cobra still has a chevrolet IRS. Yes? The set up you liked isnt that difficult of a design to copy providing you can find the uprights. They look like late model vette. If they are, whats the hold up?

Last edited by tyrellracing (10/12/2013 10:17 am)