|

|

|

|

|

You are not logged in. Would you like to login?

![]() Offline

Offline

I have all the major pieces to start a project where I'll be installing a 1993 7.5" Ford Thunderbird rear end into a 1991 Miata. The axles will be shortened to-suit but rather than respline the 4-lug Miata hubs I'd like to use the entire 5-lug Ford knuckle assembly, adapting the Miata geometry in proportion to the Ford knuckles. So, I wonder, is that at all workable?

![]() Offline

Offline

Hey Tool Man,

Not to get off track, but are you doing the whole drive train? V8 motor and all? Maybe an aftermarket crossmember?

Welcome To The Only All IRS Board!

Ralphy

Last edited by Ralphy (11/26/2011 12:18 pm)

![]() Offline

Offline

There will be a 5.0 from a 1996 Explorer and an automatic transmission from a 1993 F150. What's the fun in buying something? I plan to make/modify as much as possible.

![]() Offline

Offline

Have you measured hub to hub on both units? If so how much of a difference?

Also can you throw up some good pics of the two?

"I'd like to use the entire 5-lug Ford knuckle assembly, adapting the Miata geometry in proportion to the Ford knuckles."

I'm not sure where your going with this. Are you suggesting to keep Miata links, springs and shocks? Sounding like a real long shot.

Last edited by Ralphy (11/26/2011 5:57 pm)

![]() Offline

Offline

tool_man wrote:

There will be a 5.0 from a 1996 Explorer and an automatic transmission from a 1993 F150.

Slushbox in a Miata? Oooh, mortal sin there ;)

Think a 7.5 is good enough for a decent 5.0? I guess in a light enough car it's probably okay.

The Miata rear suspension is considerably different from the Miata, adapting the Ford upright is going to be a fair bit of work. I know the upright pivots are somewhat different but don't know how close they are dimensionally.

The 'Bird hub is 5x4.25 with a hub pilot a bit under 2.8in, it will not accept most common 5-bolt Ford wheels. The '03 Cobra hub is a bolt-on (well, press-on, the Cobras and 'Birds and Mark VIIIs used the same 28-spline outer driver and the same SET49 wheel bearing) and has the 'normal' Ford 5x4.5 bolt circle and 3.06 hub pilot, but it's ridiculously expensive (2.5x the price of a BMW M5 hub, last time I looked.) The MN12 hubs can be redrilled 5x4.5 and a press-on sleeve fabricated to sleeve the pilot to 3.06in, just a matter of whether you can do it cost-effectively.

Last edited by JEM (11/27/2011 12:44 am)

![]() Offline

Offline

I'll be using aftermarket wheels so I don't believe the wheel will be an issue. Shortening the axles has to happen so the hub-to-hub dimension will be taken care of with that. The car will weigh no more than 2600 lbs with me and a tank of gas.The 7.5" is a tested application but Frankensteining the Ford knuckles is not perhaps because it's a lot of fabrication and engineering. That doesn't worry me. What I don't want is for the end result to be one big mistake. This is supposed be a scary ride but not because of the IRS. There're reported problems including wheel hop with the Miata suspension which I imagine will require some of the same fabrication and engineering. So, I'm inclined to fix those before the fact rather than after.

I have to finish another project before I can get this one in the garage which'll be a few months. What I'm looking for today is a consensus as to whether or not it is likely the Ford knuckles can be adapted as a part of an improved design. I'll take that as my direction. With so little info I could be asking too much.

![]() Offline

Offline

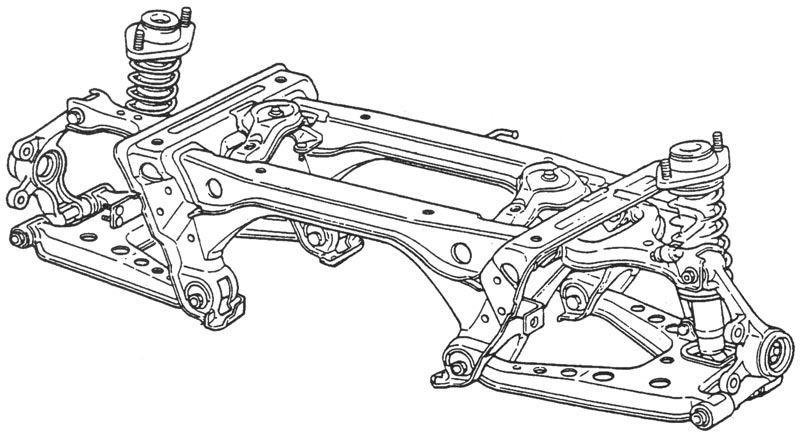

Tool Man, is this similar to what you have?

If so your not that far away from the Ford design. It would seem to me you need to start measuring all your pickup pointa with the control arms. I would guess if possible (the conversion), making new control arms would be the best way to go. One thing I have noticed with Ford is that on the knuckle. The distance between the LCA and axle are vey narrow.

I think this is a 7.5 installed in a Cobra kit.

Last edited by Ralphy (11/27/2011 8:33 am)

![]() Offline

Offline

Ralphy,

I believe that's it. Making the control arms from scratch would be acceptable. Once I provide all the dimensional stuff will the group be able to provide me with the geometry that will result in a robust design?

![]() Offline

Offline

OK so your on board with making new control arms. Why would you not want to use the same inner pivot points that you have now? Provided the distance is the same on the knukle point UCA to LCA? I would get a good level and track the angular change per inch on your Miata hub and use that as a ground point. You know Miatas better then me, have you read anything as far as camber issues that you would want to address? Add/subtract?

Again you need as exact dimensions as possible as to what you have. You have the units we cannot measure them. Something I like about the Ford is the halfshaft being so close to the LCA should reduce the amount of torque aplied under hard accelleration.

What gears do you have in the 7.5?

Last edited by Ralphy (11/27/2011 10:35 am)

![]() Offline

Offline

The design's not a mile off, but the devil's in the details. You need something of fairly similar dimensions. I can provide some basic measurements off the Ford uprights if you need them, but I know little about the Mazda layout.

![]() Offline

Offline

The ratio is 3.27:1 and I want to keep the track width stock while increasing the tread width from about 7" to 10". I will want to use the same pivot points if I can but I see it as a better choice to reconstruct the chassis than machine on the knuckle if something does have to be modified. Actually, I'm here because I only know what is obvious about any IRS but I'll have no problem assimilating anything I'm shown and I'll be able to provide accurate drawings for the complete Miata geometry as well as the measurements for the Ford knuckle. I anticipated it would be a matter of duplicating the stock Miata geometry using the Ford knuckle. How far off is that?

![]() Offline

Offline

Tool Man,

I didn't read much, but have you been to this site?

![]() Offline

Offline

Ralphy,

I've been there a bunch, asking opinions and getting ready. I've seen the post. They're working with an 8.8 which is reported to be more problematic than the 7.5.

![]() Offline

Offline

tool_man, WELCOME TO THE FORUM!!! Sorry I did not welcome you properly sooner but I have not had a lot of time to spend on the forum. The way I would approach your situation is to build the lower arms at what ever length is necessary to get the track width you desire. Then I would make the upper link adjustable. The reality is, that unless this is a track car you want camber set some where near 0º at normal ride height and by making the upper link adjustable you can facilitate that. The only way for sure to know what kind of a camber curve you will have is to take some measurements and have the info put in to solid works. Joe a member here on the forum has done this on several different project. take a look at this thread It is specific to a Jag design however the same thing could be done on solid works to look at your potential camber curve. I think Joe still checks in so you could make a post directly to him or you could email him.

![]() Offline

Offline

tool_man wrote:

Ralphy,

I've been there a bunch, asking opinions and getting ready. I've seen the post. They're working with an 8.8 which is reported to be more problematic than the 7.5.

Problematic in terms of making it fit?

I'd meant to get you a bunch of pictures and dimensions of an MN12 knuckle, but right now I'm spending my spare time (a) dragging the frame back out from under the '64 wagon and (b) moving my project writeups onto an externally-hosted Wordpress site so it won't be such a pain to maintain the things and I'll be able to write on them all in one place.

Hopefully over the weekend now I'll get to come up for air...oh, wait, we're going to see the Nutcracker on Sunday...we'll see.

Last edited by JEM (12/02/2011 10:48 pm)

![]() Offline

Offline

JEM wrote:

Problematic in terms of making it fit?

Yes.

![]() Offline

Offline

Tool Man,

See this!

Last edited by Ralphy (12/14/2011 2:40 pm)

![]() Offline

Offline

Wow. You can just find anything on Craig's List but I'm looking forward to the challenge of assembling the whole project from scratch. As far as choosing between the 8.8 and the 7.5 I'm going with the consensus of the Monster Miata crowd. They say they've never had a 7.5 give up or perhaps is was almost never. "Never" is a long time...

![]() Offline

Offline

LOL! Never is not a word I would use. Rolls Royce wouldn't say never.

Good Luck!

![]() Offline

Offline

Tool Man CL is a slow process. I use SearchTempest to search CL.

![]() Offline

Offline

Tool Man,

Again you may have seen this one, however.

![]() Offline

Offline

Haven't seen that one. He choose to retain the Miata hub and related hardware.