|

|

|

|

|

You are not logged in. Would you like to login?

![]() Offline

Offline

Hi - I have an IRS that someone else built for me. I think I'll end up making a replacement but initially, I want to tweak this one to work better.

My #1 issue is it's wearing out the bearing/hub assemblies pretty quick. I firsted noticed one of the hubs was shot after about 100 miles. They were salvage yard parts so I assumed it was bad to start with. Went ahead & replace both with new ones. Now, 3k miles later, the left side is shot again.

What would cause that?

Some background on the car & IRS...

Car

* MGB (little British convertible from the 60's/70's but I've swapped a 302 Ford, T5, & the IRS into it + done a ton of body mods.

* 2630 lbs (1300 front, 1330 rear w/full tank of gas [18 gals])

IRS -

* Custom frame

* Nissan R200S

* CV 1/2 shafts w/930 style @ differential (adapter to Nissan pattern) & Chevy S10 spline @ outboard ends.

* Custom uprights (plate steel) with Chevy S10 4x4 hubs/bearing assemblies.

* 54" width (wheel mount surface to wheel mount surface)

* 15x8 wheels, 225/50/15 tires, 1/4" spacers

* Double A-arm style; lower is true a-arm; upper is a single bar; connection points are bushings -- all in good condition.

I have some pics of the IRS but looks like I have to make some more posts before the forum will let me post them.

![]() Offline

Offline

Welcome aboard!

There is a lot to learm about suspension systems and a lot of great information is collected here regarding IRS design and installation.

Your car sounds like a neat project - can't wait for some pics - a few more posts!

About the rear wheel bearing - I am puzzled as to how your setup is the culprit. I would suspect a couple of other things. The first bearing failure could be because they were "junk." The second failures more likely because the bearings were improperly installed - too much play, wrong size, not well matched to the hub, etc. I would suspect those issues long before the actual design, unless you are getting some real wild camber/toe.chnages while driving.

BTW - Chevy S-10 hubs seem to be popular in some rear suspension mods I've seen on the net, as I recall.

Again welcome - you've come to a good place to help solve that issue!

Cheers - Jim

![]() Offline

Offline

phantomjock wrote:

Welcome aboard!

There is a lot to learm about suspension systems and a lot of great information is collected here regarding IRS design and installation.

Your car sounds like a neat project - can't wait for some pics - a few more posts!

About the rear wheel bearing - I am puzzled as to how your setup is the culprit... The second failures more likely because the bearings were improperly installed - too much play, wrong size, not well matched to the hub, etc. I would suspect those issues long before the actual design, unless you are getting some real wild camber/toe.chnages while driving.

BTW - Chevy S-10 hubs seem to be popular in some rear suspension mods I've seen on the net, as I recall.

...

Cheers - Jim

Thanks for the quick reply Jim & glad to hear it's unlikely the IRS design would be behind the bearing failures.

I don't think I have excessive camber or toe changes through the movement range -- although I don't know how to measure it. I don't see any toe change & relatively little camber change when I articulate the movement while the car is on jack stands (shocks removed).

I also don't think incompatibility between the hub & bearings would be a cause as the S10 hubs are the integral hub/bearing assemblies. The bearings aren't removable. They are supposedly sealed -- but I did modify how my shocks mount since putting the new hubs on & so did have to cut/grind & I'm sure there was plenty of metal dust from that in the area. I washed it down afterwards, but maybe the metal dust got in & ruined the hub assemblies?

As for improperly installing - again, I don't think so although I did use Google as a reference to find out the torque specs on the hubs -- 181 ft/lbs. I haven't pulled the wheel to check but maybe the nut backed off some? My half shaft stub axles don't have a hole for a cotter pin; I was told I didn't need one. Will check that when I swap the hub this weekend.

Keep the thoughts coming...

Thx.

![]() Offline

Offline

Now that I've made 2 posts hopefully the forum will let me addd the pics...

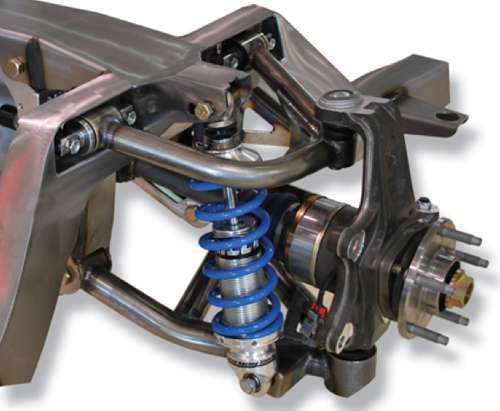

Pic #1 is the IRS in an earlier stage as viewed from under the car. Shocks mounting points have been modified since this version to be more vertical. Rides much better now. This pic gives you a feel fro the design, bushings, etc.

Pic 2 is from inside the car while I was making a modification to enable the IRS to fit right. You can see the upper control arms in this pic...

And here's a pic of my car...

![]() Offline

Offline

rficalora wrote:

As for improperly installing - again, I don't think so although I did use Google as a reference to find out the torque specs on the hubs -- 181 ft/lbs. I haven't pulled the wheel to check but maybe the nut backed off some? My half shaft stub axles don't have a hole for a cotter pin; I was told I didn't need one. Will check that when I swap the hub this weekend.

You don't have 181 ft/lbs. loaded on the bearing do you? IMO, your coilovers would do better behind the axle and stand up as straight as possible by bringing the upper mount outward. But that's another issue.

Very very nice!

Ralphy

Last edited by Ralphy (4/19/2013 12:28 pm)

![]() Offline

Offline

RE the spindle nut - yes, torqued to 181 ft/lbs. i just double checked and multiple sources call for that. examples are both the SKF torque spec book and the National Wheel End products torque spec book call for on front 1995 Chevy S10 hub spindle nuts (my IRS uses the hubs from the front of a 95 4x4 S10 which i believe is fairly commonly used on IRS's).

With respect to the shocks, I re-did how they are mounted about a little over a year ago. They are now only about 15° off vertical.

![]() Offline

Offline

When I first asked I was going in a different direction. I was thinking you may have a bind if you had some setup with two bearings or tapered bearings.

Anyhow, wow 180 lbs. that's alot. I searched four wheel drive S10 hub nut torque specs. I see 103 lbs over and over. Then I found a chart from Speedway Motors of all places that give the 180 lbs. and 103 lbs. The 103 is shown for 4 WD. Could it be possible over torqueing could distort the inner race causing the wear?

Here's another chart

Looks to me that it depends on the year. The 97 specs give both on the second chart.

Ralphy

Last edited by Ralphy (4/20/2013 3:41 am)

![]() Offline

Offline

If you go to 6:45 min, this guy says 95 ft/lbs.

Then in his second video part 2 he says 90.

Ralphy

Last edited by Ralphy (4/20/2013 4:06 am)

![]() Offline

Offline

More,

"1. If your vehicle is 4WD, one of the most overlooked and most common causes of wheel bearing failure is incorrect torque of the axle shaft nut. If you have a 2WD vehicle, then this is irrelevant. We are ASE techs who own a repair shop and we have also noticed that GM has changed some of the torques specs since factory. This has resulted in us concluding that GM may have realized the factory torque specs may have been incorrect or they have dialed them in closer to a more reliable setting."

Ralphy

Last edited by Ralphy (4/21/2013 3:56 am)

![]() Offline

Offline

Very interesting info. My hubs are a little different than the ones in the video link -- those have the ABS sensor embedded and a pig tail to connect. Mine are the style with a tone sensor ring (although I don't have ABS on my car anyway) so not sure if the specs are the same as what he says in the video.

I'm also a little confused because when I ordered I thought I was ordering the hubs for a 4x4 S10. That was about 2yrs ago so my memory is a little foggy but I recall having to verify the ones they had would work because my originals didn't have an ABS sensor ring but the only ones RockAuto had did have it. Looking at my order it says I ordered Raybestos 713061 '1992 Chevrolet S10 Pickup 4.3L 262CID V6 TBI (Z) OHV' -- doesn't say anything about 4x4?

I think I'll call Raybestos on Monday to see what they say about the Torque spec. I'll also call my local Chevy dealer's service dept & see what they say. Hopefully I'll get the same answer from both.

Also, the video you posted may be a key to my problem too. At 6:10 he pulls an O-ring off the stub axle & says something like you want to make sure that goes back on correctly... I don't have an O-ring on mine. Not sure what it's for, but the only thing I can guess is that it serves as a seal??

I can probably get some info on that from my local auto parts place.

May be getting somewhere.... thanks again for the info!!

![]() Offline

Offline

Definitely going to have to call. I stopped by a local shop that I go to sometimes. They looked it up on their subscription service -alldata or something like that and that said 140 ft/lbs?!?!

![]() Offline

Offline

We have Alldata at our place.Think also about this, those numbers are for a heavier load and on the front of a 4x4. Even if 180 was right, I wouldn't see the need for that kind of torque for your rear IRS.

Did you also notice in the video that nut comes off fairly easy? It doesn't look like the previous installer went 180.

IMO, I think you could get away with 75 ft/lbs.

Alldata

Ralphy

Last edited by Ralphy (4/21/2013 3:57 am)

![]() Offline

Offline

IMO

On another note. The builder who built that cage looks like he's been around the block a few times, really well done. Very similar to Heidt's Pro-G, except for the coilover location. Why they put the coilover behind? Even though you have something similar to an upper control arm. it's not! It has no fore and aft stability. If you were to accelerate hard the wheel assy will want to pull forward trying to twist the lower control arm down in front of the axel and up behind the axel. Adding the vehicals weight through the coilover assists in the twisting. Hard acceleration loads it even more. By putting the coilover beind the axle counters this. When braking the reverse. IMO, I've never read but lust an observation looking at countless designs. Heidt's design is a copy of a Ford T Bird with inboard brakes.

Heidts IRS

T Bird IRS

Once you pin the upper, true UCA, the effects during acceleration reverse on the lower. It wants to twist upward to the front. So now you move the coilover forward. Though less likely to move fore or aft since both are locked in place. You would probably have less problems loading either side.

Mustang Cobra

C5 C6 Corvette Roadster Shop

I can't remember the exact cause, but a guy at Club Cobra had twisted his LCA.

Ralphy

Last edited by Ralphy (4/21/2013 6:07 am)

![]() Offline

Offline

I think i figured out whee the 140 came from... All the references I've seen show 180 ft/lbs for the spindle nut on the S10 4x4 front hub up through 96 or 97 and 103 ft/lbs after that. Looks like 103 ft/lbs is the same as 140 NM. So at least I'm back to just 2 specs to choose from. Before i make my calls I'm going to do a little research to find out if the early and late S10's use the same hub. If so, maybe they updated the torque spec like was suggested above. That would sort of explain why the shop told me 140 even though i told them it was a 92... e.g. alldata probably keeps current with the varios manufacturers' service bulletins. Still gonna make the calls tomorrow.

RE: the IRS design, glad to hear it looks well done. There arw a few things I'd like to change once i get the hub situation sorted. 1st is wheel hop on accelleration.

![]() Offline

Offline

IRS wheel hop? Never heard of it here! LOL!![]()

What about anti-squat, do you have any angle in your LCA?

Ralphy

Last edited by Ralphy (4/21/2013 1:27 pm)

![]() Offline

Offline

Sounds like wheel hop isn't a problem I have on my own... where to start on that one?

Angle in the LCA - close to horizontal at ride height - haven't measured but probably about 5* angled up from the outboard end to the diff end.

![]() Offline

Offline

If your uprights were fabricated from plate steel and the bearing bores were machined before welding was finished there is a good chance that the inner and outer bearing seats are not concentric. In this area even the smallest amount of run out either axially or radially will cause premature bearing failure. When I made my uprights I did all the welding first then mounted the upright to a face plate so I could cut the inner and outer bearing seats in the same process. In other words I did not remove the piece from the lathe chuck until the bearing carrier was finished. In this way the distortions created by welding do not move the bearing seats. This is one of the best ways to assure concentricity of the wheel bearings. If any welding was performed to the uprights after the counter bores for the bearings was finished there a good chance the welding distorted the bores. At the very least it will make the bores out of round and that is as detrimental to bearings as run out.

Another note. Most front wheel drive wheel bearings have the inner and outer bearings or cones ride on a common outer race or cup. The high torque figures you quoted usually are what is used to this all in one type bearing. The outer race is designed so when the nut is torqued the two inner races make contact and create the ideal pre load. Since every thing rides on that one nut holding it together the OEM's tend to put a substantial preload on the nut to streatch the splined shaft at the end outer CV. This ensures that when a severe load is encountered there is no elasticity left to allow the bearings to seperate. If you look up the torque figures for axle nut on front wheel drive vehicles of similar weight to the S10 you will see these high figures are common to the majority of them.

Last edited by tyrellracing (4/22/2013 12:18 am)

![]() Offline

Offline

His bearings are self contained, no bore to machine.

Something like this.

Some may disagree, but the coilover to the front may be a big issue wrapping up the LCA. Your suspension is all Heimed out, that's good no rubber. I just read tire sidewalls could be an issue. Maybe pump about 80 psi into them and see what happens. Another IMO, I think you could add another link behind your UCA. Triangulating the upper, making the inner mount of elongated and radiused, like so ). Setup the camber and toe etc... with it unattached. once set with the car jacked up with coilover out reattach the link and cycle the suspension up and down by hand. Trust the feel, IMO the bind would be zero to little. This would allow for no need tomove the coilover? Hmmm?

If you look at post #2 at the below link, is a guy who 4 point mounted his uppright and raced. The differential is Corvette C3.

Ralphy

Last edited by Ralphy (4/22/2013 3:54 am)

![]() Offline

Offline

Good news/bad news on the torque spec... got a hold of Raybestos & they say I have it right at 180 ft/lbs for that hub. So unless the torque wrench I borrowed is off something else is causing the problem. The good news is they offered to have their lab analyze my hubs to see if they can determine cause of the wear. I have to go through RockAuto so have to call them tomorrow, but at least that should give me some clues for where to look.

Also, Raybestos tech said my hubs are fully sealed so don't need any sort of o-ring on the back.

Interestingly, I searched RockAuto today for replacement hubs & they've apparently removed all the after market ones for S10 pickups. I checked 92 & 95 for a range of models & all they show now are ACDELCO hubs at about $250 a pop -- compared to $60-100 for after market. I'm going to call them to see what's up with that -- other than maybe they got a deal on them and are trying to move them.

I'm going to focus on the hubs till I get that addressed, then I'll move on to the wheel hop.

![]() Offline

Offline

Okay, here's what I see at AllData 1995 S10 pickup.

Nut (120). Tighten to 245 N.m (181 lbs. ft.). Note: Insert a drift or large screwdriver through brake caliper into rotor vanes to prevent from turning (fig. 45).

So now I start going forward in years. I only needed to get to 1997 and I got this.

Hub and Bearing Assembly To Steering Knuckle Bolts 105 Nm (77 lb ft)

Front Wheel Hub Bolts 130 Nm (95 lb ft)

What's different about the two. Are they different part #'s?

At quick glance I see some of the same part #'s at Rock Auto.

95

,carcode,1061053,parttype,1636

97

[url],carcode,1061109,parttype,1636[/url]

Ralphy

Last edited by Ralphy (4/24/2013 8:00 am)

![]() Offline

Offline

Based on the pics I've seen, the hub PN changes. The "early" S10 hub has a tone ring for the ABS where the "late" S10 hub has some more of the ABS components in the hub -- not sure if the sensor is built in or not but there's a pigtail coming from the hub on the "late" ones.

![]() Offline

Offline

Took a pic while replacing the hub. You can see how I redid the shock mount vs. how it was originally (pics above). Shock is forward of the 1/2 shaft. Suggestions for what to do to eliminate the wheel hop on moderatly hard acceleration?

![]() Offline

Offline

Hi rficalora,

Your upper arm does very little to stop the lower arm from twisting when an acceleration load is applied at the whee/hub center. The twisting/untwisting of the lower arm results in wheel hop. You need to triangulate the upper arm into a true "A" arm to help contain the accleration force.

Also, take a look at how your pinion is restrained. Up and down motion of the pinion will also induce wheel hop.

hope this helps,

Irstang

![]() Offline

Offline

![]() Offline

Offline

Excellent info both!! I actually typed up a reply last evening asking if forward or trailing links instead of converting to true A arms would work -- then my 14yr old son jumped on me (he loves to try & take me by surprise) & in the ensuing trouncing he got I lost everything I'd typed -- the FFR pics above look exactly like what I had in mind & I think would be a lot easier due to space available on my car than converting upper link to A arm. I was a bit worried about caster change with that sort of set up though. Thoughts on that? I only have about 3" of compression travel.

![]() Offline

Offline

Also - any idea what that upright/hub assembly is from? I've thought about remaking my control arms to make alignments easier as well as to adjust so I don't need the spacers I'm running (current need 1/4" spacers to keep the control arms from hitting the back of the rim lips). I have Chevy 5x4.75 lug pattern and S10 hub splines so would need to find upright & hub assemblies that would work with those.

![]() Offline

Offline

The only problem with the trailing link is that it moves in an arc. Causing a bind with the LCA, which does not match the motion between the two. I'm not saying it can't be used, it binds a bit. Maybe a call to FFR may give better info.

A step better is the Watt's link.

"Also - any idea what that upright/hub assembly is from?" T Bird, it's your OEM knuckle.

Ralphy

Last edited by Ralphy (5/06/2013 10:22 am)

![]() Offline

Offline

rficalora -

Is that 3" from ride height - or overall? If overall travel = Full bounce to Full jounce - you'll find many options for shocks/dampers and won't blow them out. Limiting suspension travel is not a bad thing - less opportunity for camber/toe changes. Sacrifice is perhaps body roll and comfort.

As Chapman said; "Any suspension will work if you don't let it..."

Cheers - JIm

![]() Offline

Offline

The FFR parts are essentially shock absorbers. I was hoping you could find room for a true radius rod running aft or forward.

![]() Offline

Offline

3" from ride height. May be a little less than that, but it's in that range.