|

|

|

|

|

You are not logged in. Would you like to login?

![]() Offline

Offline

I found a MII aftermarket front suspension the other day. I bought lower A arms, upper A arms and Carrera coil overs with springs for $250.00. The parts were a little rusty so I started to bead blast them. However the whole package was never used. Equaled about $1,400.00 in parts.

Ralphy

![]() Offline

Offline

wow you stole that!!! About the best price I have found was a kit you can by where you get all the brackets precut and you bend them and then weld them together. didn't include any of the actual suspension parts like springs arms or spindles and it was still more than $250.00 Why were they selling it so cheep??? how well do they work on a Cobra I know they are a OK but not great option for the Mustang.

![]() Offline

Offline

Many of the Cobra kits have MII front suspension. Mine is one, however I have all factory parts. This will replace the strut rod lower with an A arm. It also gives me the coil overs so I can adjust height. I had to destroy the uppers urethane bushing to disassemble. I found McMaster Carr sells urethane bar stock. What I have found so far is that I want urethane with about a 90 durometer.

The guy had bought a 64 Falcon with the whole thing installed and never used. It weathered a little sitting outside. He decided the body was to much work. He still has the aftermarket cross member that could be cut out. He also gave me the MII spindles and 4 lug rotors.

I may need to move the lower coil over mounts lower on the control arm. I will not know until I put it together. However working in a machine shop with 40 welder co-workers? LOL I'm also going to re-weld some areas to make nice, TIG! Mustang II is probably the most used suspension configuration in the aftermarket speed industry. Year One builds a Chevy II kit. I'm almost sure it has a MII front suspension.

If your ever on Craig'sList and are searching something unique and your willing to drive to get it or have it shipped? Search Tempest will search a region by zip code and distance. Use key words etc... It's great!

Last edited by Ralphy (8/22/2011 6:17 am)

![]() Offline

Offline

I never mentioned this before. We have a plating shop, MPI, FPI, vapor greasers, bead blast, X-ray, eddycurrent, plasma spray, HVOF, heat treat, welding and a huge machine shop. We even do thermal coatings! Guys were coating piston tops, etc... I probably missed some things. Oh we also have a composite shop. I just need to find the right time and make friends! LOL

PolyU

Last edited by Ralphy (8/22/2011 6:29 am)

![]() Offline

Offline

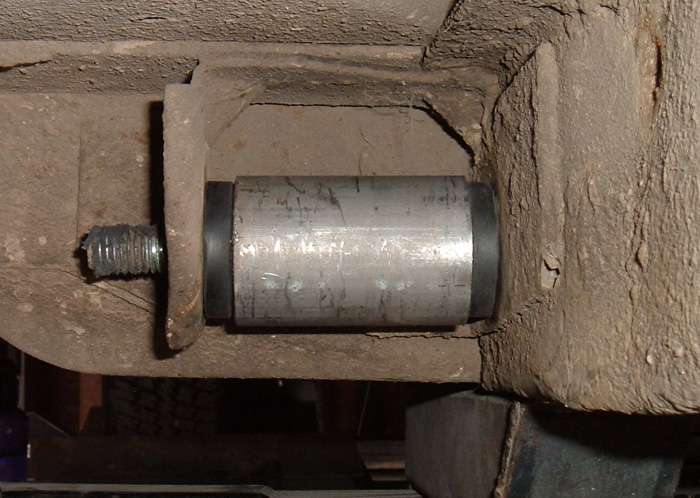

I removed all the bushings and blasted all my parts. The poly bushings in the upper would not come out. The way that they go in makes it a "I used a word I shouldn't have" to get them out. There's a steel sleeve that fits inside the poly and it fits tight. About a .005 interference it locks the poly in place. The only thing you can hit on is the upper A arm cross shaft end and it hits the soft poly bushings. The bushings being snug just stay put. A 900 pound gorilla couldn't get them out. So we put the assy. on dry ice to make the poly harder. That did it but the poly busted. So I will have to buy new bushings. I found McMaster Carr sells poly bar stock in all sorts of durometer ratings. I think they are 90 durometer.

Warning never assemble a upper control arm till you know you will not take it apart. Cause it ain't gonna happen!

Last edited by Ralphy (8/30/2011 5:22 am)

![]() Offline

Offline

Went to Airgas today and bought some TIG rod. I'm going to learn how to TIG weld on my front LCA's. Guys at work said I should groove the existing MIG welds then TIG over them. The plate welded between the 1" tubing has two welds about 4" long with about a 2 1/2" long gap between. I'm going to weld from end to end. ![]()

Last edited by Ralphy (8/30/2011 7:55 pm)

![]() Offline

Offline

Ralphy wrote:

I removed all the bushings and blasted all my parts. The poly bushings in the upper would not come out. The way that they go in makes it a "I used a word I shouldn't have" to get them out. There's a steel sleeve that fits inside the poly and it fits tight. About a .005 interference it locks the poly in place.

You couldn't press the sleeve out??? any time I have had that situation I have pressed the sleeve out and then the bushing pops right out. Never worked with Mustang II parts but have removed (and installed) lots of different bushings in this manner. In fact thats how I did the bushings at both ends of my IRS sub frame

Thread from the original forum about my bushings

![]() Offline

Offline

No I couldn't. my LCA'a are similar to what you show. However the UCA's have the cross-shaft trapped between ends, we tried to grab the bushings with needle nose pliers, but it was not going to happen. It's a case of, you have to remove the cross-shaft before you can remove the bushings. But you have to remove the bushings before you can get the cross-shaft out.

UCA

LCA

Last edited by Ralphy (8/30/2011 10:13 pm)