|

|

|

|

|

You are not logged in. Would you like to login?

1 of 1

1 of 1

![]() Offline

Offline

I used a "new" tool today out in my garage, a scaler

I was cleaning 50 years worth of rust, dirt and oil build up (not to mention a layer of paint that had been sprayed over the top) off of the 9" differential I recently purchased. If you have ever cleaned one of these (with out the benefit of a total tare-down and a parts washer) you know they can be a real pain. The ribs on the case make lots of corners that pack up with oil and dirt and there is no way to get a wire wheel in there to clean them out. A wire brush and a screw driver works OK, but the oil dirt build up after 30-50 years is rock hard and brushing it and chip at it with a screw driver takes a lot of work so you could spend the better part of a day getting it fully stripped and ready for paint. With this air tool I had mine fully stripped in about 30 minutes. I was able to get in to all the nooks and crannies, and it only took me about 15 more minutes with some carb cleaner and a rag to finish the job. This tool is worth its weight in gold.

Any way all this got me thinking, A guy on my Galaxie forum posted a fantastic brake flaring tool by K-tool, I am posting about a scaler, what other good tools are out there that I don't know about. Feel free to post and share which tools are a must have. Just to clarify I am not talking about wrenches pliers and screw drivers that we all need, I am talking about more advanced tools that make the project go easier.

![]() Offline

Offline

Nobody has any other great tools that thay want to share info about???

![]() Offline

Offline

I started to post several times. Then I balked!![]()

Ralphy

![]() Offline

Offline

balked??

![]() Offline

Offline

Anyone got a picture of a checkbook?![]()

Last edited by 303Radar (1/22/2013 4:30 pm)

![]() Offline

Offline

This is an engine assembly tool , but it sure saved me alot of aggravation. Oil sump Installer.

I have been wondering if a scaler would be a good investment or not.

![]() Offline

Offline

Balk: A donkey balks when it refuses to move forward. Demands are something people often balk at like a donkey refusing to move. In baseball, a pitcher balks when he or she begins a pitch by winding up, but does not complete it. It is as if he is refusing to complete a started pitch, and it is against the rules.

And I like that big orange hammer need many of those.

How about a couple of inexpensive picke forks?

Last edited by Ralphy (1/23/2013 4:49 pm)

![]() Offline

Offline

I know the meaning of "balk" just wondering why ![]()

![]() Offline

Offline

Maybe to obscure? We rebuild engine seals in our dept. The requires removal of Hastiloy Honeycomb. Which is brazed in during a heat treat step. This braze is some of the toughest crap I ever cut, wears out even the best carbide money can buy. Once we shuck out the honeycomb we try to remove as much as possible without touching the parent material of the ring it's brazed into. We've used all types of drum sanding, hard wheels, etc...

Well one day I was using a ziss wheel and noted. "damn they cut so well, hmm... So I got the hair brained idea to stack 4 new .060 wheels, making a 1/4 wheel. Dressed the four even. Someofabitch do they cut! So well that I now have pretty much everyone in our shop doing the same.

You can just fit 4 wheels on our arbors like these.

Last edited by Ralphy (1/23/2013 5:52 pm)

![]() Offline

Offline

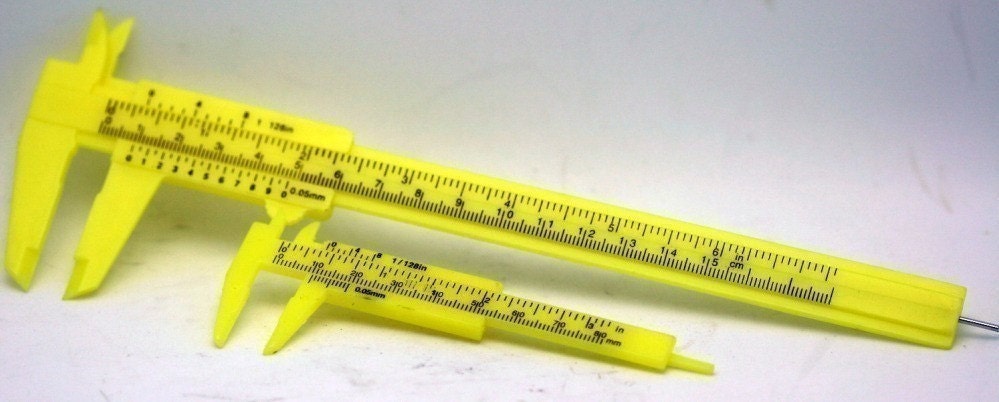

Even a cheap caliper like this is a must. Plus no gears or electronics to break.

Ralphy

Last edited by Ralphy (1/25/2013 2:39 pm)

![]() Offline

Offline

Poor Man's Brass Hammer

A must have tool when welding up small holes in sheet metal is a brass hammer. This is especially true when the metal is thin. Hold the face against the backside and mig up the hole. I made this one with an old ball peen and a brass freeze plug.

Last edited by irstang (4/21/2013 11:22 am)

![]() Offline

Offline

RalphWell one day I was using a ziss wheel and noted. "damn they cut so well, hmm... So I got the hair brained idea to stack 4 new .060 wheels, making a 1/4 wheel. Dressed the four even. Someofabitch do they cut! So well that I now have pretty much everyone in our shop doing the same.

You can just fit 4 wheels on our arbors like these.

[img wrote:[/img]

Ralphy - I''l Bite. What are Ziss WHeels? Air drive cut-off wheels that go "zzzzzissss?" I've binged/and googled and can't find em. Sounds like a cool trick - but what/where are they?

Cheers - Jim

![]() Offline

Offline

Yes!

We always called cut off wheels, ziss wheels, sorry about that. We cut/grind on some tuff metals at work. We also have access to all types of wheels. It's always been a struggle doing metal removal. So one day I had just noticed the .060 cut off wheels were pretty bad ass. So I took four of them stacked and dressed them with a dog bone/abrasive stone. Damn it does cut like a champ. I showed this to a couple of other guys at work. Now everyone does the same.

Dog Bone

Side note: Lately I've been making fixtures at work. Heat treat fixture for sizing diameters and returning engine parts to flat. A couple of metals for this are Rene 41 and 330 stainless. Damn talk abot slow progress. The 330 SS can work harden just like that. Then you have to go back and remove the spot even slower.

Ralphy

Last edited by Ralphy (4/20/2013 3:16 am)

![]() Offline

Offline

Up here in the great white north those wheels are usually referred to as zip wheels.

1 of 1

1 of 1