|

|

|

|

|

You are not logged in. Would you like to login?

1 2 Jump to

1 2 Jump to

| Independent Rear Suspension Forum » Is there any reasonably priced software for assessing an IRS design? » 7/06/2017 7:10 pm |

I didn't get any replies on my question about ways to assess an IRS design without software so I'm guessing that means that's not a viable option. Is there any reasonably priced software - lets say $150 or less? Or is it all way more than that?

| Independent Rear Suspension Forum » Is there a way to assess IRS geometry without software? » 7/05/2017 8:37 pm |

No suggestions?

| Independent Rear Suspension Forum » Is there a way to assess IRS geometry without software? » 6/30/2017 3:00 pm |

I'm thinking learning geometry & the formulas is beyond me so I'm wondering whether there are services that:

a) given various measurements, will provide back the info about camber (& toe if any) changes throughout the suspension travel

b) make recommendations for what to change to improve the IRS

I'm asking because I have an IRS that someone else made (I got no specs on it) & I had to modify to make it fit my car so changed it anyway. Net, I have no idea what it's doing and want to because I want to change a few more things. I'm thinking 1st step is figure out what it's doing currently & then make my modifications incorporating recommended changes from the analysis.

| Independent Rear Suspension Forum » Triumph Spitfire Redo » 6/30/2017 2:51 pm |

I'll second the recommendation not to cut/weld. My IRS had welded axles and one broke 2nd time out. Not fun. If you can't find an interchange or cut & respline one end, there are shops that will make a CV axle any length you want with any splines. Or you can just order the shaft & assemble with your bird cage, flanges, stub axle, etc.

| Independent Rear Suspension Forum » New guy - lots to learn - some early questions » 1/20/2014 12:45 pm |

Well, my IRS was designed and built 8 or 9 years ago. I don't think Factory 5 or anyone else was making an IRS for them at the time so it was probably the brave souls who paved the way (or at least broke the ice) for the manufacturers to realize the market was ready.

| Independent Rear Suspension Forum » New guy - lots to learn - some early questions » 1/20/2014 11:34 am |

The Nissan axles were not designed to go with the S10 hub assemblies. They just happen to fit. The back story is that the guy who made the whole IRS on my car had made one for himself. He had an MG and was a Nissan guy so he swapped the turbo charged Nissan motor in and used Nissan IRS components to make his IRS. He wanted to make more and sell them to the MG engine swap crowd (which is a bigger audience than you might think). I wanted an IRS, didn't know how to make it so he and I worked out a deal. Problem was I already had my wheels and they're drilled 5x4.75 and the Nissan hubs couldn't be redrilled to that. So, he did some research and found that a lot of Cobra kit guys used S10 hubs and they happened to use the same diameter & spline the Nissan used. So, he modified his upright design to work with the S10 hubs, narrowed the Nissan and narrowed the Nissan axles. Execution on narrowing the axles wasn't great - weld penetration was only about 3/16" and they weren't sleeved or re-heat treated. Took a few years for me to finish building my car. 2nd time out just test driving in the neighborhood, one of the axles snapped. Wasn't even accelerating hard; just making a left turn pulling away from a stop sign. Looking at the axle pieces was when I realized how they had been narrowed. Considered rewelding and sleeving, but got mixed reviews on how that'd hold up. And, where they were cut meant the weld and sleeve was right in the area the boot is supposed to clamp down.

Talked with the builder but he wasn't prepared to make it right and had lost confidence in him, so bit the bullet and had axles made by "the drive shaft shop". They knew all about the S10 hubs and said they made axles for a lot of racers with them. They are well known and have great reviews so I trust the stub axle is known to work well with the bearing/hub assemblies (more on this in a moment). And, I've found their customer support is awesome. As an example, I mis-measured one side

| Independent Rear Suspension Forum » New guy - lots to learn - some early questions » 1/19/2014 5:00 pm |

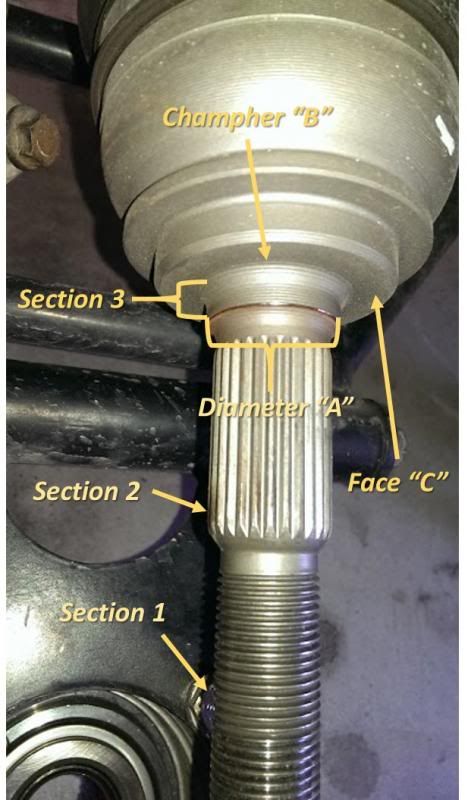

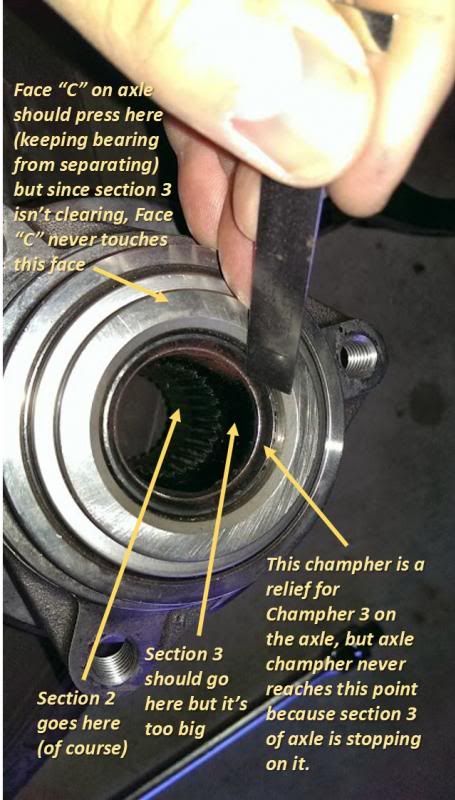

You are right Ralphy. I looked at it some more and the champher in the bearing/hub is jus to clear the transition to section 3. So, I'd just need the stub axle champher trimmed back - a bit more than .070. That was the difference in diameters. I didn't measure it, but the horizontal distance that the bearing is away from the face on the stub axle is more like 1/16". The bearing fits correctly on my old Nissan stub axle so I think that rules out having the wrong bearing. But, it is possible my newer axles are set up for a different year rang S10. Swapping bearing assemblies would definitely be easier than machining the stub axle. With luck the folks where I got the axles will be working tomorrow and I can check.

| Independent Rear Suspension Forum » New guy - lots to learn - some early questions » 1/19/2014 11:52 am |

I think I finally get what you were trying to tell me Ralphy - if I were to modify just the front portion of section 3 -- effectively making section 3 shorter, that would let the bearing/hub assembly fully seat. I'm wondering if that flat section (section 3) is supposed to be inside the bearing now or not... maybe it's just a bit too long & adjusting that campher would work after all. I don't think I'd want to try & file that area off, so likely still means disassembling the CV to get the stub axle turned on a lathe - just turning down that champher instead of the diameter of section 3 area.

| Independent Rear Suspension Forum » New guy - lots to learn - some early questions » 1/19/2014 10:17 am |

RE: In view #2 is that a gap between the axle and bearing? -- Yes... because section 3 on the axle is too big to fit into the bearing/hub assembly. Pics below may help explain what's going on.

| Independent Rear Suspension Forum » New guy - lots to learn - some early questions » 1/19/2014 7:10 am |

It's hard to describe Ralphy, but if you look at the stub axle picture, the threads are one diameter; lets call that section one of the axle. Then the splines are a bigger diameter, we'll call that section two. Then after the splines, the diameter bumps up again (section three) and you can see the whiney ring at the leading edge of that section. Section three is about .070 (7 hundredths, not .007) larger diameter than the inside diameter of the bearing assembly. If you look at the bearing pic, there is a similar ring scratched in that I'm pointing to with the ruler. That spot is where section three is hitting it and it is hitting on the champher inside the bearing. Modifying the champher won't help; I'd either need to turn down section three of the axle or the inside of the bearing.

My current axles are custom made, but in an earlier version I had shortened Nissan axles. The Nissan stub axle diameter and spline match the S10 which was part of what led us to the S10 bearing/hub assemblies. I checked the Nissan stub axle and it goes on all the way and seats properly.

I don't think turning the bearing out is a good idea for several reasons... Potential to get debris in the bearing, may be too hard, and, would mean I'd need machining if I had to replace a hub out on the road some day. Option two is to simply swap the current stub axles for the Nissan ones. Haven't looked to see if they are the same length and designed for the same axle diameter - but if my memory is right, the axle was smaller diameter. Last option is to turn down the current stub axle (including the radius leading to the face that mates with the flat on the back of the bearing/hub so turning down section three doesn't create a stress riser at that transition. Option two would be the fastest answer it everything lines up, but I want to talk with the place I got the axles first because I don't want to lose support from them if needed if they don't like the idea of me modifying them.

| Independent Rear Suspension Forum » New guy - lots to learn - some early questions » 1/18/2014 5:31 pm |

While I'm posting pictures, here are a couple of the uprights. I was wrong & they are 1/2" with the extra 1/2" welded on the outboard side. That extra 1/2" wasn't originally added for strength; the guy who built it mismeasured & the control arms were hitting the inside of my wheels. That 1/2" was supposed to correct that (ended up that I still needed a 1/4" spacer.

| Independent Rear Suspension Forum » New guy - lots to learn - some early questions » 1/18/2014 5:06 pm |

Ok, took it apart today... I may very well have some twisting going on and I don't like the upright or LCA designs; so, I'll likely eventually redo them. What donors should I be looking at? I'm not planning to change wheels so need something that has or will work with or be redrilled to 5x4.75 lug pattern & fit 15" wheels. Ideally there'd be an IRS from something that I could either simply narrow the cage or remake one with the same control arm pick-up points so I don't mess up the geometry.

In the meantime, I have finally figured out why my hubs are wearing (coming apart actually) so quick ![]()

![]()

![]() . First clue was when the stub axle wouldn't come out easily. Remember these have only been on for a few months and about 600 or 700 miles ago. And, the car rarely sees rain and is stored inside a garage. I made a simple puller from some angle iron & a bolt & it popped loose, but I'd not had one stick after being on for such a short time. Then, when taking a picture for this thread, I noticed a shiney ring on the stub axle -- it's a thin line & doesn't look shiney, but there's a worn ring on the axle and the flash picked it up.

. First clue was when the stub axle wouldn't come out easily. Remember these have only been on for a few months and about 600 or 700 miles ago. And, the car rarely sees rain and is stored inside a garage. I made a simple puller from some angle iron & a bolt & it popped loose, but I'd not had one stick after being on for such a short time. Then, when taking a picture for this thread, I noticed a shiney ring on the stub axle -- it's a thin line & doesn't look shiney, but there's a worn ring on the axle and the flash picked it up.

So, I started looking closer. What I found is the inner diameter of the hubs is about 7 hundredths of an inch smaller than the raised portion on my stub axles making them not seat properly. Since the area is hidden inside the upright, I'd not noticed that before. Now I just need to decide what to do about it. Axles were made by The Driveshaft Shop in Salsbury NC. They do a ton of driveshafts and CV axles for the race crowd; I'm pretty sure they'll stand behind it & either swap out the stub axles or maybe turn that section down a little.

[img]

| Independent Rear Suspension Forum » New guy - lots to learn - some early questions » 1/15/2014 5:22 pm |

Hi Tyrellracing - I hope you dontnthink I intentionally ignored input from you or anyone else. You guys know so much more than me I think some of the comments are above my head and I don't always catch it.

On the uprights, they are 3/8" plate with 1/2" plate welded to that around the perimeter. Not sire if that's visible in the pics (I'm on my phone and can't see the detail). I'll post some better pics of them when I have it apart this weekend, but given that info, does it still seem likely that the uprights are distorting? Or maybe they got distorted when the 1/2" plat was welded (TIG) to them?

Thanks again!

| Independent Rear Suspension Forum » Wearing hubs out every 5-700 miles » 1/14/2014 7:42 pm |

I had posted about this problem before but thought I'd inadvertantly put a worn hub back on instead of a new one. Now it's about 600 miles later & the new hub is worn out again. I know I torqued it right - even double checked with a 2nd torque wrench to be sure mine was accurate. What else would make bearing/hub assemblies wear out that fast?

It's like they are separating because after I knocked out the lugs the play in the hub was gone -- that leads me to think knocking out the lugs pressed it back together. I will be looking this weekend, but the only think I can think of is the splines on the stub axle don't go deep enough for the "bell" on the CV isn't pressing against the back of the hub assembly. Does that sound viable? Other reasons for this sypmtom?

| Independent Rear Suspension Forum » New guy - lots to learn - some early questions » 5/20/2013 11:28 am |

Ok, now that I'm past the hub & wheel hop issues, I want to start thinking about reworking portions of the IRS itself. Initially, my goals are:

a) to enable use of wider tires

b) likely to replace the bushings with something stiffer &/or heims to eliminate (minimize?) changes in camber or toe due to bushing "compliance".

b) to lighten it

c) to make it easier to align

And, before I start changing anything, I want to determine how good or bad the geometry is so I can address if I need to at the same time.

That all means I need to learn. What books or articles do you guys recommend?

| Independent Rear Suspension Forum » New guy - lots to learn - some early questions » 5/19/2013 11:22 am |

It's been a couple of weeks, thought I'd give a quick update... wheel hop must have been related to the bad hub as now that I've fixed that, I'm no longer getting it. More and more I'm thinking I inadvertantly put one of my used hubs back on when i replaced them about a year ago. Thinking I've had a bad hub from the start and it just got worse over time.

As for the uprights twisting, I doubt it. They are 1/2" plate and are a double layer welded around the perimeter where the stub axle comes through - which is one of the reasons i want to re-do them... let's say they are not light.

| Independent Rear Suspension Forum » New guy - lots to learn - some early questions » 5/07/2013 5:40 pm |

OK, that makes sense. Presumably longer is still better. By inner fulcrum you're saying on a plane parallel to the center line if the car (front to back) and intersecting the upper arm's pivot point, right?

Now, if I have to make a choice between doing that where it's only a few degrees off the existing UCA (maybe ending only a few inches forward of the UCA inner pivot or more of a forward link like the FFR pics (but true radius rod) which would be preferable and why?

There's very little room in that area to work with.

| Independent Rear Suspension Forum » New guy - lots to learn - some early questions » 5/07/2013 5:00 am |

I think I'll have room for a radius rod... asssuming longer is better to minimize the effect of the arc it'll move in... likely will be able to run it from the UCA to the front hanger where the solid axle leaf springs used to hang.

| Independent Rear Suspension Forum » New guy - lots to learn - some early questions » 5/06/2013 6:34 pm |

3" from ride height. May be a little less than that, but it's in that range.

| Independent Rear Suspension Forum » New guy - lots to learn - some early questions » 5/06/2013 8:59 am |

Also - any idea what that upright/hub assembly is from? I've thought about remaking my control arms to make alignments easier as well as to adjust so I don't need the spacers I'm running (current need 1/4" spacers to keep the control arms from hitting the back of the rim lips). I have Chevy 5x4.75 lug pattern and S10 hub splines so would need to find upright & hub assemblies that would work with those.

| Independent Rear Suspension Forum » New guy - lots to learn - some early questions » 5/06/2013 8:07 am |

Excellent info both!! I actually typed up a reply last evening asking if forward or trailing links instead of converting to true A arms would work -- then my 14yr old son jumped on me (he loves to try & take me by surprise) & in the ensuing trouncing he got I lost everything I'd typed -- the FFR pics above look exactly like what I had in mind & I think would be a lot easier due to space available on my car than converting upper link to A arm. I was a bit worried about caster change with that sort of set up though. Thoughts on that? I only have about 3" of compression travel.

| Independent Rear Suspension Forum » New guy - lots to learn - some early questions » 5/04/2013 9:39 am |

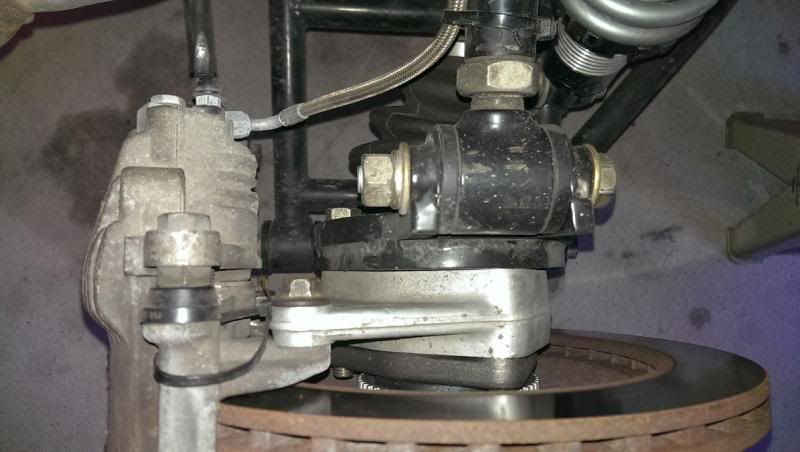

Took a pic while replacing the hub. You can see how I redid the shock mount vs. how it was originally (pics above). Shock is forward of the 1/2 shaft. Suggestions for what to do to eliminate the wheel hop on moderatly hard acceleration?

| Independent Rear Suspension Forum » PhantomJock's IRS Build Thread » 4/24/2013 7:27 pm |

OK, now there's a lot going on in that one photo; cant wait to see more. Is the LCA adjustable in both vertical and orizontal planes?

Think you said it's a track car, is your plan to leave it infinitely adjustable?

Also, what will keep the LCA's from twisting under torque? They look lighter/smaller than mine and i'm only running 225's with a mild small block Ford 302. Don't know how much motor you have, but tires that fill up the rest of the space you have should hook up pretty well.

| Independent Rear Suspension Forum » New guy - lots to learn - some early questions » 4/24/2013 11:43 am |

Based on the pics I've seen, the hub PN changes. The "early" S10 hub has a tone ring for the ABS where the "late" S10 hub has some more of the ABS components in the hub -- not sure if the sensor is built in or not but there's a pigtail coming from the hub on the "late" ones.

| Independent Rear Suspension Forum » PhantomJock's IRS Build Thread » 4/23/2013 6:04 pm |

Very col stuff. i like a couple of the uprights. The one's you've designed appear tall and wide at the top. What size wheels are you planning for? Could be an illusion but looks like you'd need some pretty big spacers if your wheels aren't pretty big.

| Independent Rear Suspension Forum » New guy - lots to learn - some early questions » 4/22/2013 6:27 pm |

Good news/bad news on the torque spec... got a hold of Raybestos & they say I have it right at 180 ft/lbs for that hub. So unless the torque wrench I borrowed is off something else is causing the problem. The good news is they offered to have their lab analyze my hubs to see if they can determine cause of the wear. I have to go through RockAuto so have to call them tomorrow, but at least that should give me some clues for where to look.

Also, Raybestos tech said my hubs are fully sealed so don't need any sort of o-ring on the back.

Interestingly, I searched RockAuto today for replacement hubs & they've apparently removed all the after market ones for S10 pickups. I checked 92 & 95 for a range of models & all they show now are ACDELCO hubs at about $250 a pop -- compared to $60-100 for after market. I'm going to call them to see what's up with that -- other than maybe they got a deal on them and are trying to move them.

I'm going to focus on the hubs till I get that addressed, then I'll move on to the wheel hop.

| Independent Rear Suspension Forum » New guy - lots to learn - some early questions » 4/21/2013 9:13 pm |

Sounds like wheel hop isn't a problem I have on my own... where to start on that one?

Angle in the LCA - close to horizontal at ride height - haven't measured but probably about 5* angled up from the outboard end to the diff end.

| Independent Rear Suspension Forum » New guy - lots to learn - some early questions » 4/21/2013 6:37 am |

I think i figured out whee the 140 came from... All the references I've seen show 180 ft/lbs for the spindle nut on the S10 4x4 front hub up through 96 or 97 and 103 ft/lbs after that. Looks like 103 ft/lbs is the same as 140 NM. So at least I'm back to just 2 specs to choose from. Before i make my calls I'm going to do a little research to find out if the early and late S10's use the same hub. If so, maybe they updated the torque spec like was suggested above. That would sort of explain why the shop told me 140 even though i told them it was a 92... e.g. alldata probably keeps current with the varios manufacturers' service bulletins. Still gonna make the calls tomorrow.

RE: the IRS design, glad to hear it looks well done. There arw a few things I'd like to change once i get the hub situation sorted. 1st is wheel hop on accelleration.

| Independent Rear Suspension Forum » New guy - lots to learn - some early questions » 4/20/2013 4:04 pm |

Definitely going to have to call. I stopped by a local shop that I go to sometimes. They looked it up on their subscription service -alldata or something like that and that said 140 ft/lbs?!?!

| Independent Rear Suspension Forum » New guy - lots to learn - some early questions » 4/20/2013 9:50 am |

Very interesting info. My hubs are a little different than the ones in the video link -- those have the ABS sensor embedded and a pig tail to connect. Mine are the style with a tone sensor ring (although I don't have ABS on my car anyway) so not sure if the specs are the same as what he says in the video.

I'm also a little confused because when I ordered I thought I was ordering the hubs for a 4x4 S10. That was about 2yrs ago so my memory is a little foggy but I recall having to verify the ones they had would work because my originals didn't have an ABS sensor ring but the only ones RockAuto had did have it. Looking at my order it says I ordered Raybestos 713061 '1992 Chevrolet S10 Pickup 4.3L 262CID V6 TBI (Z) OHV' -- doesn't say anything about 4x4?

I think I'll call Raybestos on Monday to see what they say about the Torque spec. I'll also call my local Chevy dealer's service dept & see what they say. Hopefully I'll get the same answer from both.

Also, the video you posted may be a key to my problem too. At 6:10 he pulls an O-ring off the stub axle & says something like you want to make sure that goes back on correctly... I don't have an O-ring on mine. Not sure what it's for, but the only thing I can guess is that it serves as a seal??

I can probably get some info on that from my local auto parts place.

May be getting somewhere.... thanks again for the info!!

1 2 Jump to

1 2 Jump to